The exponential growth of Peru’s blueberry industry is not only a boon for producers, but service providers had to scale up rapidly to meet the demand for millions of plants, substrates, containers, and the like. Alvaro Ramirez, commercial director of Matritech, an input supplier, has witnessed the rapid changes in Peru’s world-leading blueberry production.

“Blueberries growth in Peru was exponential with around 30% growth in the last years. Peru exceeded 287,000 tons in the last season, and projections for the 2023-2024 season is to reach over 338,000 tons. Growth in hectares planted is decreasing. However, varietal change and production systems are increasing. We began focusing on hydroponics, at the beginning, we started working with early adopters, medium size companies who bet on quality instead of quantity. In addition, the new hydroponic systems allow greater productivity in less time, although the investments are higher, maintenance costs can be reduced. Reducing water use is essential, and hydroponic systems are making a great contribution. For sure, you are aware of the market price curves and all that happened. Most of that exponential growth was based on soil and Biloxi. Major companies covered the market and set up their programs and distribution networks. Now the time of premium varieties has come, companies started replacing Biloxi, from soil to pots, from traditional to hydroponics,” explains Ramirez.

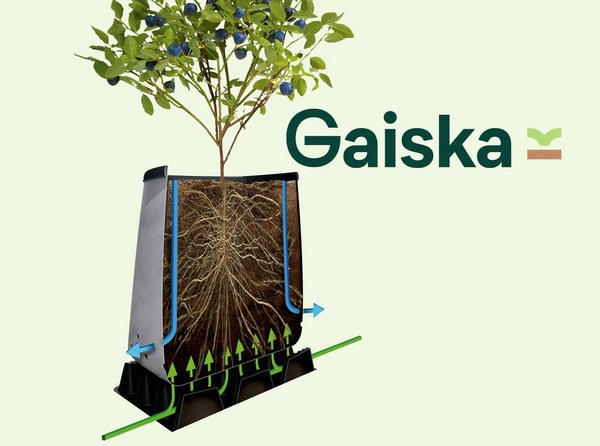

Matritech is a plastic product manufacturer in Peru, with their processes of extrusion, injection, and thermoforming, known for their Gaiska brand. They supply thermoforming pots, plastic substrate containers, drainage spacers, and gutters, among other products for hydroponic blueberries. Their experience covers four years and up to three million plants considering all products, says Ramirez.

During the 2022/2023 season, Peru exported 287,806 tons of blueberries at a value of $1,4 billion. ProArandanos, Peru’s blueberry industry body, is estimating an 18% increase in volumes to reach 338,859 tons and $1,5 billion during the 2023/2024 season that has just started. Peru’s blueberry industry has grown from 1,900 hectares in 2016 to over 17,900 in 2022. In 2016 an average of 5% of the hectares were in pots, that has increased to 19%, with 3,400 hectares of blueberries now grown in pots and 14,500 hectares in the soil. In 2016 about 53% of hectares was Biloxi, this is now down to 27% with an average of 4,800 hectares of Biloxi.

“Peruvian producers have been innovating to overcome the different climates, for this reason, today they continue testing different substrates on the market and validating the importance of oxygen in the roots. Imports of coir between 2021 and 2022 have been doubled,” states Ramirez.

Peru’s coastal desert-like areas were transformed to produce what is now often referred to as the blue gold. “For instance, the Peruvian coast is a desert with warm seasons and a natural greenhouse, but sometimes it turns, so complicated planning is needed. In some areas, humidity reaches 95% in winter, and we need to set up our products for that condition. On the other hand, there are several wrapped-up solutions. For this reason, we have a team, we are launching a brand. We visit clients in their fields. We set up test plots, we validate our products not only based on our experience but also on the needs of every different area and crop planning. We have also collected information about the state of the crops, the yields, how they are installed, and the upcoming projects. To sum up, we went through the process of converting from a product manufacturer to a partner with the producers that we serve.”

“We learned a lot along the way, and we understand that there is a big difference between early adopters and Biloxi replacers. Companies that started up in hydroponics master crop management, they know how. Companies that are replacing varieties constantly receive information from different sources, and they don’t have enough internal information based on experience to compare with. This is our challenge now,” concludes Ramirez.

For more information:

Alvaro Ramirez Gutierrez

Matritech

Tel.: +51998178118

Email: [email protected]

www.gaiska.com