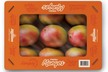

A new linerless packaging format has been introduced for Kissabel® Naturally Red-Fleshed Apples in the UK fresh produce market. The project was developed through cooperation between packaging technology provider Ravenwood Packaging and its approved linerless label printer, ProPrint Group. The linerless fruit lid was produced on the Com500 Coater and applied using the Nobac 5000L linerless applicator.

The development represents the first UK application of a 3×2 linerless apple pack format. It follows an earlier 2×2 linerless apple format developed for the Sassy™ brand, also owned by Mansfield, which holds the Kissabel brand.

© Ravenwood Packaging

© Ravenwood Packaging

The Kissabel Rouge variety entered UK retail on 2 December in a plastic-free linerless pack. The packaging format consists of a linerless fruit lid combined with a cartonboard tray. According to the parties involved, the format was designed to support recyclability and compatibility with high-speed packing operations while aligning with the existing Kissabel branding.

The linerless fruit lid and tray format was developed in collaboration with Worldwide Fruit, the Kissabel design team, and Smurfit Westrock. The new 3×2 configuration builds on a previously launched 4-pack design. All packaging components are intended for kerbside recycling.

Application of the linerless lids is carried out using the Nobac 5000L fresh produce applicator. The system is designed for automated placement of linerless labels at commercial packing speeds. Trial runs for the Kissabel project were conducted at Ravenwood's facilities to establish application settings. The first production run followed seven working days after final artwork approval.

The project forms part of a broader move within the apple category toward linerless and plastic-free packaging formats. Earlier developments for Mansfield included a linerless 2×2 pack for Sassy apples, using similar application technology.

The introduction of the Kissabel 3×2 linerless format reflects ongoing interest within the fresh produce sector in reducing packaging materials while maintaining pack integrity and operational efficiency.

For more information:

Ravenwood Packaging

Tel: +44(0)1284 749144

www.ravenwood.co.uk