Vervit, an in vitro cultivation specialist, wants to use a new vertical farm to make significant strides toward the future of food supply. With this new facility, the Belgian company aims not only to optimize the adaptation phase of in vitro cultivated plants but also to scale up microgreens production and stabilize their quality.

© Vervit

© Vervit

"That can take between four and 12 weeks, depending on the kind of plant," says Juan Carlos Pérez. Until recently, that adaptation phase took place elsewhere: in greenhouses or at a subsidiary in Spain. But thanks to the new vertical farm, Vervit now completely controls that process, he adds.

Vertical farming: controlled innovation

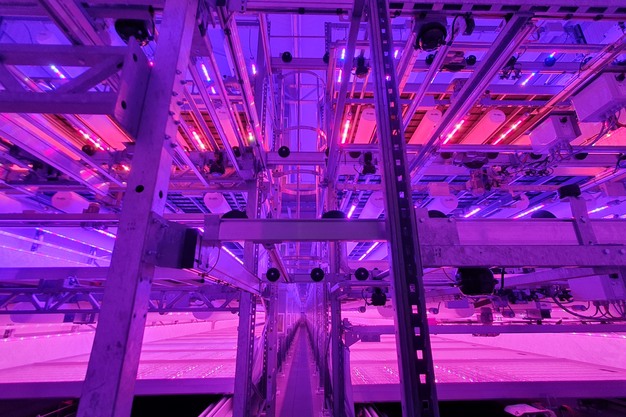

Vervit's vertical farm covers 1,000+ m² in four levels. The bottom two are set up for lab plant adaptation, the other two for microgreens. "We can optimize each level's humidity, temperature, and light cycles, tailored to the plants' specific needs." That is highly beneficial for microgreens, which grow in seven- to ten-day cycles. "In that short time, light significantly impacts the plant's shape, flavor, and growth," says Juan Carlos.

© Vervit

© Vervit

"We can use the vertical farm to play with day lengths and light intensity to get the best end product. Even a few days of cloud cover can have a major effect." Vervit produces microgreens - from niche to mainstream - under its PachaGreens™ brand, and the company is the largest player in that market in Belgium. "In the hospitality and retail sectors, that adds an extra dimension to the products," explains Juan Carlos.

Interest in microgreens is growing rapidly, partly thanks to their high nutritional value and antioxidant content. "In America, microgreens are already almost a commodity. Here in Europe, though, the market is still gradually expanding. That shows that microgreens aren't only healthy, but also interesting from a culinary perspective."

© Vervit

© Vervit

High-tech bioreactors and in-vitro expertise

A key distinguishing feature of Vervit is its combination of in vitro expertise and proprietary technology. "From our in vitro plants, we produce and supply the first, disease-free 'mini tubers' which go on to traders and growers," says Pérez.

Sustainability and circular production

The vertical farm also contributes to the company's sustainability goals and creates potential for new varieties and markets. "In vitro cultivation plus adaptation in a controlled vertical farm, and microgreen cultivation, open up new market opportunities. We can, thus, not only improve quality, but also expand the selection of seeds and offer products that are almost impossible to cultivate outside or in traditional greenhouses."

© Vervit

© Vervit

Also, innovation remains central. "We're always experimenting with light, climate, and substrates. That leads to better quality, but also to added seed and otherwise hard-to-grow product choices," Juan Carlos concludes.

For more information

Vervit bv

Raveschoot 9A

9080 Beervelde

België

E: [email protected]

T: +32 9 397 18 16