The current fiscal year is also marked by inflationary price rallies for processors and convenience food manufacturers, which in turn are making it difficult to plan purchasing and sales. "At the beginning of the year, sales to the catering industry weakened noticeably, while communal catering remained almost unchanged. We are currently seeing strong price pressure, as some products have recently become significantly cheaper on the spot market. The best example is potatoes: the outlook is particularly bleak for independent producers without storage facilities and long-term contracts," sums up Henrik Rolf, co-managing director of Köckerling GmbH & Co. KG in the Paderborn region.

The company's own farm primarily produces potatoes and pumpkins.

"Raw material prices are only one component in the overall structure," explains Rolf. "What is putting us under increasing pressure is not so much the prices of goods themselves as the secondary costs: from the increase in the minimum wage and rising social security contributions to ever more complex bureaucratic requirements. The latter in particular has increased significantly in recent years, from mandatory origin labeling to customer-specific requirements under the Supply Chain Act. Added to this are the foreseeable PPWR packaging regulation and additional CO₂ costs due to national emissions trading. Even if raw materials become cheaper, the effect is quickly offset as long as operating costs and time expenditure continue to rise. Prices can therefore only ever be assessed in relation to the overall cost situation."

Insight into the fresh-cut processing at Köckerling. In the case of lettuce, the company has already largely switched to imported goods from Spain.

Process thinking instead of improvisation

According to the company, the bulk consumption segment appears to be becoming more professional in the long term. Rolf: "We are seeing a strong trend away from improvisation and toward process thinking. This, in turn, is linked to the increasingly acute labor shortage: there is a lack of chefs and kitchen staff in many places, which is further driving the demand for fresh-cut products from centralized kitchens. As a supplier and manufacturer, this naturally makes us more productive on the one hand, as we also process many things automatically. On the other hand, due to higher demand and increased customer requirements, we also have higher technical costs. This means, for example, that we need more specialists such as technicians and electricians, but we also have to factor in higher maintenance and investment costs for our machinery."  © Köckerling GmbH & Co. KGThe company's customer base also includes some catering suppliers at wholesale markets in western and northern Germany.

© Köckerling GmbH & Co. KGThe company's customer base also includes some catering suppliers at wholesale markets in western and northern Germany.

Fresh-cut as an everyday product rather than a luxury item

Köckerling's wide range of products now includes over 1,000 individual items, from potato products and cut vegetables to high-convenience items such as wraps and delicatessen products. Following the increased demand for fresh-cut products, the product category is now also being evaluated differently, Rolf observes. "Fresh-cut products are no longer a luxury item: we are seeing a strong trend toward simplified processes in terms of convenience. After all, kitchens have to make do with fewer and fewer staff, so unnecessary effort should be avoided when it comes to the product in question. We are seeing this trend across the entire range, whether fruit, vegetables, or potatoes."

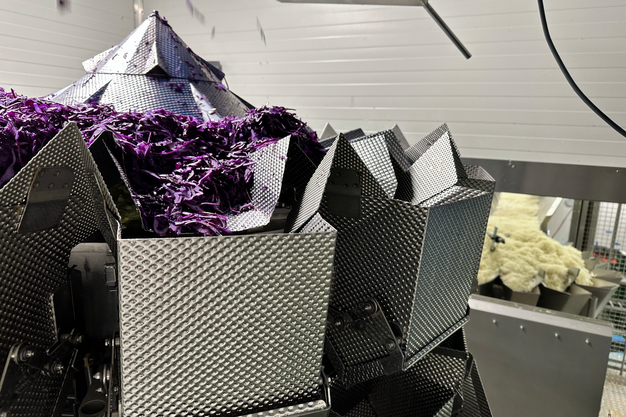

Multihead weigher

Digitalization and increased efficiency

The task in the coming years will be to streamline existing processes and thus increase efficiency within the company. "We are consistently focusing on digitalization and Industry 4.0," says Rolf. "That's why we have converted our merchandise management system to a modern solution tailored to our processes. The goal is seamless networking of employees, systems, and products. We want to continue along this path in the coming years so that we can continue to offer customer-centric solutions, he concludes.

For more information:

Henrik Rolf

Köckerling GmbH & Co. KG

Im Brinkort 6

33129 Delbrück

Tel. 0 29 44 - 97 97 70

info@köckerling-frische.de

www.köckerling-frische.de