"What looks like a good batch on the outside can turn out to be mostly ruined inside. Fusarium, core rot, and neck rot are silently spreading through onion stocks, costing growers their customers, margins, and peace of mind. Studies confirm it's getting worse every year. Our team sees it too: many storage sheds no longer smell fresh. That's deeply concerning. That's why extra attention must be paid this year to the "sick" onions in storage to prevent further spread. And to save what can still be saved", says Jouke van der Meer of Ellips.-Elisam.

© Ellips B.V.

© Ellips B.V.

"We can't cure infected onions. But we can help remove them with advanced AI technology. This ensures your batches meet the quality standards your customers expect, while protecting your sales and your reputation."

© Ellips B.V.

© Ellips B.V.

Traditional technology only sees the outside

"Many packers still rely on 'free-fall' finger sorters". These machines sort based on external quality but miss what really matters: internal defects like fusarium, core rot, and neck rot. Those are the silent killers in your batch. They cause internal damage that is hardly visible to the naked eye but leads to serious problems. It costs you customers, quality, and kilos."

Think about:

- Infection of healthy onions during storage or export

- Batches being rejected after delivery

- Claims and damage to your reputation

- Loss of supply security with major customers because you can't meet their standards

- And unnecessary waste of product, time, and trust

© Ellips B.V.

© Ellips B.V.

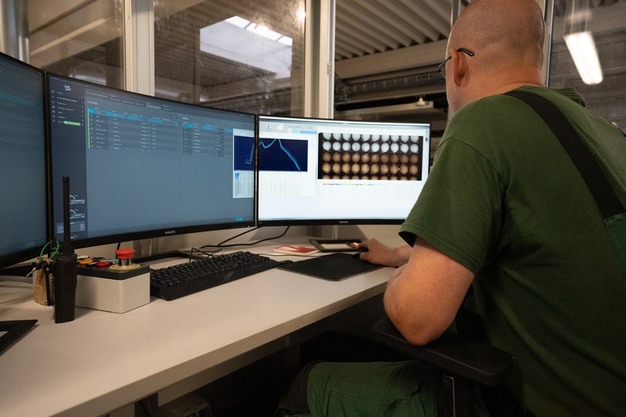

Internal and external quality in one flow

"With Ellips–Elisam, you can detect these internal problems. Fast, reliable, and with high accuracy. More than 50 onion growers and packers around the world already rely on Ellips–Elisam technology. Just in the past year, 20 companies switched to Ellips True-AI. For good reason."

"Ellips AI software is used worldwide in combination with Elisam grading machines. These lines are specially developed for high speed and maximum accuracy when sorting onions. Thanks to the smart cup system, where each onion is scanned individually and completely, you see more than just the outside."

"The technology detects both external and internal quality issues, such as fusarium, neck rot, and core rot, and ensures that defective onions are intercepted in time. This ensures your batches are thoroughly cleaned and accurately sorted, so only top-quality onions reach your customers."

© Ellips B.V.

© Ellips B.V.

Proven results, even under difficult conditions

Independent customer research shows that our solutions perform best when it comes to sorting both external and internal quality. The actual waste percentage is also significantly lower compared to traditional "free-fall finger sorters".

In other words, despite the challenging conditions this season, our solutions result in:

- Retaining your reputation (and your customers)

- Minimal claims and complaints

- Maximum value and yield despite internal quality issues

- Actual waste reduced to an absolute minimum

- More control and certainty over what does and doesn't leave your line

"The result? Cleaner batches, satisfied customers, and business owners who can sleep soundly again."

"The outside looks good, but the inside tells a different story. Thanks to Ellips technology, we now actively sort for fusarium, core rot, and neck rot." Volker Peters, Groka

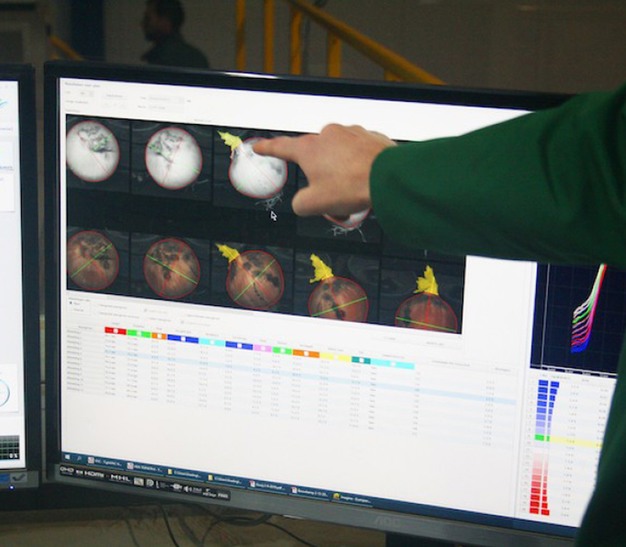

How internal quality detection works

"The internal quality technology from Ellips–Elisam uses two advanced vision techniques. First, NIR cameras (near-infrared) scan each onion at multiple points, up to two or three layers deep. This makes early defects in the outer layers visible quickly."

"The second technology is based on light transmittance. High-powered near-infrared light is projected through the entire onion. On the other side, a spectrometer measures how much light is transmitted. By analyzing this spectral data, the system determines the biochemical condition of the onion's flesh, right down to the core."

"If abnormal or diseased tissue is detected, the system automatically directs the onion to the correct exit. For processing or as waste. This way, risks are removed in time without unnecessarily losing healthy onions."

"With the new AI system, we've seen a clear improvement in defect detection. Both internal and external. Waste levels have dropped, complaints have gone down, and growers now get more accurate data on their crop", Ben Collins, Stourgarden.

© Ellips B.V.

© Ellips B.V.

Test it yourself in Wenatchee

"We warmly invite onion growers and packers to test their own batches on our Demo Machine in Wenatchee. Bring your own onions and see with your own eyes how effectively our AI technology detects both internal and external defects. After sorting, we cut the onions open so you can see exactly what has been intercepted and how much quality remains", says Rowan.

Location: Ellips USA Demo Center – Wenatchee - Washington

Location: Ellips USA Demo Center – Wenatchee - Washington

Contact: Rowan Parmenter

+1 (425) 495-3378

[email protected]