Researchers in Victoria are testing crop load management techniques to improve fruit quality and yield consistency in European pears. While thinning is standard in apple production, data on effective pear thinning remains limited, with cultivars responding differently to available tools. The research, part of the five-year PIPS 4 Profit Pear Production Systems for Future Climates (AP22002) project, focuses on developing cost-effective strategies to optimise yield and quality under local conditions.

© APAL

© APAL

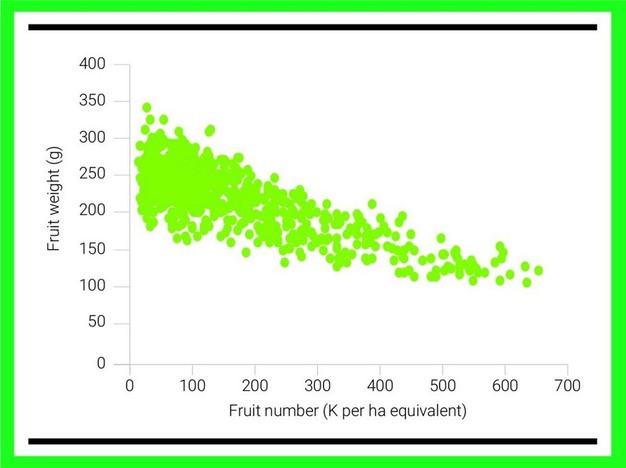

In pears, there is a negative linear relationship between crop load and fruit size, as higher fruit numbers reduce carbohydrate availability per fruit. Early thinning before cell division is completed allows more resources for the remaining fruit and reduces the risk of biennial bearing. Natural fruit drop occurs in three waves, but in heavily set trees, natural shedding does not sufficiently reduce crop load or improve fruit size.

Current tools being evaluated include pruning, artificial bud extinction (ABE), mechanical thinning, and chemical thinning. Hand thinning remains labour-intensive and often occurs too late to be effective. Pruning is considered the first step in crop load management, reducing the number of floral buds and improving light distribution. Precision pruning limits fruiting buds to a predefined number, while ABE involves manual bud removal before flowering to control both fruit quantity and position. Trees managed under ABE carry fewer, stronger buds, reducing late fruit drop and resource waste.

© APAL

© APAL

Mechanical thinning, increasingly used due to high labour costs, relies on tractor-mounted string thinners such as the Darwin and BAUM devices. These are most effective in two-dimensional tree structures with narrow canopies. Mechanical thinning is applied from white bud to petal fall, and success depends on canopy structure and flower morphology.

Chemical thinning is also being studied using hormonal growth regulators and blossom desiccants to reduce excess fruit. The effectiveness of chemical thinners depends on cultivar, timing, and environmental conditions such as humidity and temperature. Sequential spray programs using both blossom and post-bloom thinners are being tested to improve predictability and control.

© APAL

© APAL

Replicated trials at the Tatura SmartFarm and a commercial orchard in Ardmona are comparing ABE and hand thinning timing in Rico™ and Lanya™ pears. Mechanical thinning trials using the Darwin string thinner are underway, and new studies are assessing the use of a leaf blower for petal removal. Further work will examine newer thinning compounds, including 1-aminocyclopropane-1-carboxylic acid (ACC), SARsil (liquid potassium silicate), and ammonium thiosulphate (ATS).

Early results indicate that structured crop load management improves fruit size, packout, and return bloom, with ongoing evaluations in the 2025–26 season to confirm efficacy and economic performance.

© APALFor more information:

© APALFor more information:

APAL

Tel: +61 3 9329 3511

Email: [email protected]

www.apal.org.au