Across India's protected cultivation sector, automation is often adopted incrementally. Greenhouses and indoor farms add sensors, controllers, and software layers over time, frequently from different suppliers, leaving growers to manage systems that do not always communicate effectively.

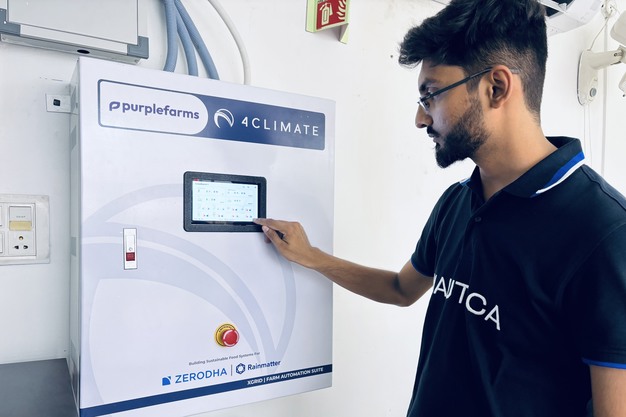

India-based agritech company 4Climate has developed its automation platform around this reality. The company positions its work around running day-to-day farm operations in a way that reduces manual intervention while remaining adaptable to different farm structures.

"4Climate provides a full-stack, modular automation suite designed specifically for indoor vertical farms and protected cultivation," says Founder and CEO Subhajit Sinha. "Each component of the hardware, software, and intelligence stack works together to deliver precise, data-driven control across greenhouse and vertical farming operations." © 4Climate

© 4Climate

Control that stays on the farm

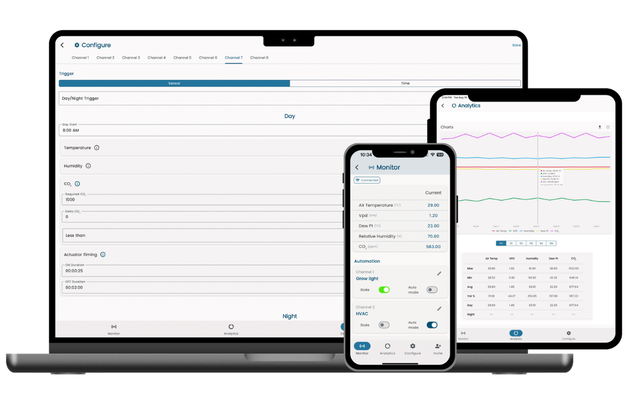

At the base of the platform is continuous environmental and operational monitoring. Sensors track key environmental and operational parameters across the growing environment. "This real-time data forms the foundation for precision control," Sinha says.

Rather than pushing all decision-making to the cloud, 4Climate processes control logic locally through proprietary IoT edge controllers. "Our edge controllers manage all on-site operations, including irrigation, fertigation, climate equipment, lighting, and actuators," he says. "By processing data locally, the system ensures low-latency operation and remains functional even during network disruptions."

Automated fertigation and irrigation units deliver nutrient recipes based on crop stage and zone requirements, with sensor feedback allowing continuous adjustment. "Precision dosing and real-time feedback help reduce water and nutrient losses while maintaining consistency across crop cycles." © 4Climate

© 4Climate © 4Climate

© 4Climate

Managing zones rather than averages

Commercial farms rarely behave as uniform environments. Differences in structure, crop density, irrigation layout, and airflow create localized conditions that require separate control. "In a typical commercial greenhouse or indoor farm, operations are divided into zones," Sinha says. "Each zone can behave differently depending on crop type and growth stage."

4Climate's controllers support up to 32 configurable output channels mapped to field equipment. "Control logic is driven by real-time sensor inputs combined with time-based and rule-based triggers," he says. "This allows each zone to operate with its own climate and nutrient parameters." As farms expand, additional controllers are added rather than replacing existing infrastructure, with all units synchronized through the company's FarmOS platform. © 4Climate

© 4Climate

Deployment scale and farm mix

According to Sinha, the company's footprint has expanded substantially. "We have over 125 CEA installations across India and the MENA region," he says. "Our automation systems are managing more than two million square feet of combined farm area and supporting produce worth over $6.5 million annually."

Most installations are in protected cultivation rather than fully indoor farms. "About 85 percent of our deployments are in hi-tech and naturally ventilated polyhouse greenhouses. The remaining installations are in indoor vertical farms and speed breeding facilities." © 4Climate

© 4Climate

Reported outcomes from commercial farms

Sinha points to customer-level results reported across multiple commercial deployments, particularly among growers transitioning from traditional practices into protected environments. "Across several installations, growers have reported yield increases in the range of 25 to 40 percent per crop cycle compared to pre-automation baselines," he says.

Automation has also changed how labor is allocated. "By automating irrigation, fertigation, climate modulation, and data logging, farms are reporting a 30 to 50 percent reduction in manual labor hours. In some five-acre greenhouses, the number of people required for daily operations has been reduced by almost half."

Adapting to regional variation

India's protected cultivation sector includes naturally ventilated polyhouses, fan-pad greenhouses, and fully indoor farms, often within the same region. "The choice of farm structure depends on local micro-climate, subsidy frameworks, and project CAPEX," Sinha says.

4Climate's deployments are adjusted accordingly. "Based on these conditions and grower preferences, we deploy the automation configuration that makes sense for that farm," he says. "The objective is reliable performance and a return that aligns with the grower's economics." © 4Climate

© 4Climate

From rule-based control to predictive layers

Current control decisions are governed by crop-specific setpoints and rule-based logic processed at the edge. "We already move beyond single-parameter control," Sinha says. "For example, we use VPD rather than humidity alone, and nutrient uptake trends rather than static EC values."

The next phase focuses on historical data analysis. "Over the next few months, we plan to release a predictive farm intelligence platform. By analyzing data across crop cycles, we can identify stress patterns, equipment drift, and conditions that affect yield."

Integration, expansion, and cost considerations

4Climate manufactures a significant portion of its own hardware while maintaining compatibility with third-party equipment. "We have integrated large HVAC systems, CO2 generators, and advanced lighting solutions," Sinha says. "Interoperability is important because farms rarely rely on a single supplier."

Over the past year, the company has expanded beyond India into Qatar, Oman, the UAE, and Saudi Arabia. As the company develops its next phase, cost remains a central consideration. "One of the ongoing challenges in CEA is the cost of automation," Sinha says. "Our focus is on delivering systems that perform reliably while remaining accessible to growers operating at scale."

For more information:

4Climate

Subhajit Sinha, Founder and CEO

[email protected]

www.4climate.in