For many companies, waste is a constant challenge. Variable input products combined with stable quality expectations at the end of the chain often lead to food waste. Polysense, a start-up from Gent, wants to tackle that challenge with AI applications.

"That it is a problem many companies suffer from is, of course, obvious. But before we really started developing technology, we first looked at where waste streams mainly originate," explains Yarne De Munck, co-founder of the company. "This showed that the biggest problem lies primarily in the food industry. The parameters of production processes often remain static, while inputs vary enormously. This creates a lot of variation at the end of the process, and part of the production falls outside the quality requirements. This leads directly to waste. We want to solve exactly that problem."

© Polysense

© Polysense

Yarne De Munck (CEO), Lucas Van Dijck (CTO), and Jarne Bogaert (COO)

Automation as the first step

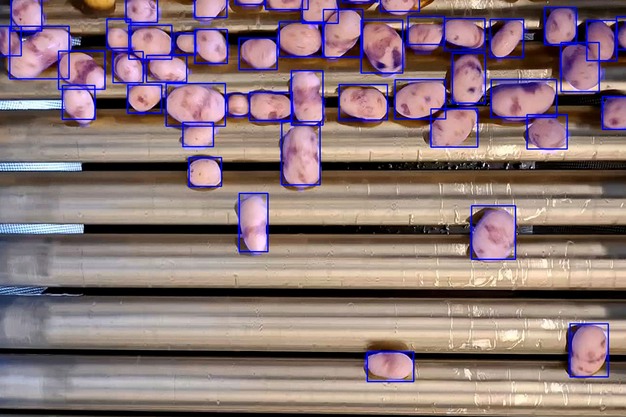

And so the focus turned to technology to address this, with Polysense concentrating on AI applications in production processes to reduce waste and increase efficiency. "First, we fully automate inline quality control. Currently, quality control in the food industry is still often done manually. The process is time-consuming and subjective. Only a small part of the production is checked, so deviations are often detected late or are not traceable at all. Full inline control gives us objective data on every product. This allows us to dynamically optimise process parameters and guarantee stable output without waste streams."

A concrete example is potato peeling. "Using vision systems, we assess each potato: how much skin is left on it? We then automatically control the peeling machines. This way, we prevent both over- and under-peeling, and operators are no longer needed in this process."

© Polysense

© Polysense

From potatoes to fruit and vegetables

However, the principle is not limited to potatoes but applies to many products within the food industry, Yarne assures. "For now, though, we mainly focus on potato, fruit, and vegetable companies and industrial bakeries, where there is a lot to be gained. Take mould detection, for example. A mouldy product can spoil entire packages. By removing these products at an early stage, we prevent defective products from reaching the shop. That has a major impact on waste reduction."

The company has been operating for about three years now. "We started with three people and have now grown to just over 30 employees. A recent €2m investment round has helped us expand the team further. This allows us to better support the market and further develop the product, especially at a technical level. Particularly internationally, we are seeing strong traction."

© Polysense

© Polysense

Market under pressure

Demand from the industry is high, Yarne confirms. "The food industry is under pressure, especially in Europe. Companies are constantly looking for ways to work more efficiently and improve margins. Any technology that helps reduce waste and improve the bottom line immediately becomes interesting. Every kilo of waste avoided is literally a kilo of money that would otherwise be lost." This is also reflected in Polysense's client base, which already includes companies such as Agristo, Roger & Roger, Aviko, and Warnez.

Polysense deliberately chooses to focus on food. "By specialising, we build domain-specific knowledge and deliver value faster. The willingness to deploy technology such as AI comes less from innovation and more from necessity. Companies need solutions for waste reduction and margin improvement. The technology itself becomes secondary, as long as the result is clear."

Ambitions for the future

In the longer term, Polysense aims to increasingly fulfil the role of 'Food Factory Partner'. "We want to help food companies worldwide with challenges such as labour shortages and automated quality control. We want companies with a lot of variation in inputs to be able to produce a stable, high-quality output, not only in Belgium and the Benelux, but worldwide."

© Polysense

© Polysense

Yarne sees that there are still a few other solutions on the market that can offer what Polysense provides. "Many other platforms are generic. Food has unique challenges: living products, seasonality, and variation. That complexity requires a specialised approach, and it is precisely that niche that sets us apart."

Debut at Fruit Logistica

The still relatively limited level of technological knowledge in the food sector means investing heavily in international connections. This is why Polysense can currently be found at many trade fairs worldwide, from Gulfood in Dubai to a debut at Fruit Logistica in Berlin. "We travel extensively and speak with companies so they understand how we can help. Once they see the possibilities, they are often willing to cooperate. Spreading that knowledge remains essential."

For more information:

Polysense

Amelia Earhartlaan 2/0301

9051 Gent, Belgium

Tel: +32 (0) 784 354 767

[email protected]

www.polysense.ai