According to Jan-Pieter, that cooperation is, therefore, a must. “You can no longer see processing and packing as single components. Today, different machines in the production chain hardly communicate with each other. However, increasing interdependence requires an integral approach. By bundling forces, Onion Tech Alliance approaches projects from a wider perspective, which increases efficiency significantly. OTA offers a single partner and a single integrated solution for the whole process. "

This does not mean that a customer is obliged to do business with all OTA members. “You cannot force anyone; it is up to us to explain to the customer that this alliance offers so many benefits that he sees it as the best solution. Aligning different solutions can be quite challenging and OTA can assure customers its solutions work well together. There are not so many changes to the cost. The benefits for the customers are especially in the synergy, unburdening and the security, or perhaps the avoidance of uncertainty, "says Jan-Pieter.

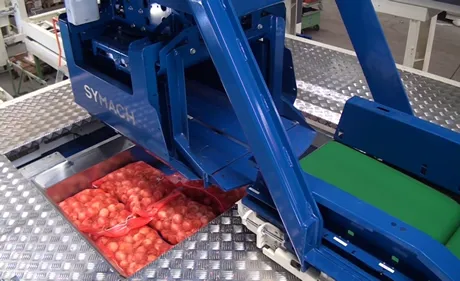

Although OTA's optical sorting technology gets a lot of attention, and Symach is convinced that this is the future, the way of sorting is not that important for Symach's palletization solution. "When the products are packed, we can process them. For us, the way in which the onions are packed has more impact. We offer solutions from small to large packages and from bags to crates and boxes. The professionalization effort that companies make, lead to more and more links with ERP systems. Our a

dvantage is that we have already gained a lot of experience in the industrial sector connecting our solutions to ERP systems. "

dvantage is that we have already gained a lot of experience in the industrial sector connecting our solutions to ERP systems. "" This year, OTA has already taken great projects in the global onion sector, such as in the United States, France, and Benelux. Last month, in Terneuzen, we worked hard on a complete end-of-line solution with multiple palletizers for processing onions in the United States. In addition to several palletizers, the solution consists of pallet transport with rolling conveyors and turntables, bag transport from multiple packing lines and overhead turning arm wrapper. We are already looking forward to the moment we have fully installed the line and the customer will run production with the full OTA solution, "Jan-Pieter concludes.

For more information:

Jan-Pieter Grootendorst

Symach

Tel: +31 115 685 625

Mob: +31 621 461 394

Jan-Pieter.Grootendorst@thieletech.com

www.symach.nl

www.oniontechalliance.com