“So what we decided to do is to refocus on the domestic market. We want to understand what is needed more, so we can improve our system to meet these demands. We have been speaking to growers, logistics providers and chain stores. We found out that some of these parties started to adopt the use of monitoring devices. We are now working to explore how these devices can work for our clients.”

Tina Sun (middle) together with Austin Gu (right) the Managing Director of Cydiance. They were meeting with a client at the Fresh Logistics Asia Exhibition held this June in Shanghai.

“For example, we met with a Hami melon producer from the West of China. This company is providing Hami melons to over 500 supermarkets across the country. They have an extensive cold chain network that includes a number of cold storage facilities in different cities. They shared an interesting narrative with us. In the past, when they did not use temperature controlled transport, they would lose around 10% of their crop during transport. Nowadays they work with temperature controlled transport lines. However, they realised that, if there are problems along the way with the temperature, losses can go up to 30%. This is significantly higher than in the previous situation.”

“What is critical here is that it shows that if these logistic developments are not implemented well or used correctly, they can cause losses instead of generate gains. This implies that monitoring devices will become increasingly important.”

“Secondly, we spoke with a logistics company that imports fresh fruits from abroad. This company imports the goods and delivers them to warehouses located in different cities. This company works predominately with third party trucks. As such they are looking to adopt a system that gives them increased control over transport within China.”

“These developments show that use of temperature monitoring devices will grow. The question is how to best meet this demand. The Chinese fresh produce industry is an upcoming market. The market is huge. However, price is still an important factor. Current devices on the market have been derived from the pharma industry and offer more complex solutions. As such they are not well designed for the fresh produce industry. A design that is less complex, easy to adopt and more affordable could be more suitable. We would love to hear from end-users what their perspective on this is. We want improve our system accordingly to better fit with the fresh produce industry”

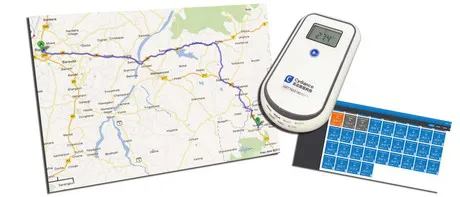

Chinese tech company Cydiance has launched two in-transit temperature data logging systems, which the company distributes in the US, Middle and South America, Europe and Mainland China. So far Cydinace has offered two pieces of equipment that can be used for temperature inspection during the process of transportation. The first piece of equipment can work independently during the logistics. Upon arrival at the destination, a temperature record report will be generated to show the change of the temperature during the whole process. As for the second equipment, it can maintain contact with online application software to display real-time temperature. It can connect to the internet automatically via long distance, and all the temperature related information can be sent through SMS and email. Both pieces of equipment can not only provide the temperature inspection data, but also a detailed record for the change of location and humidity level.

Tina Sun, Managing Director

Tina Sun, Managing DirectorCydiance Technology

Tel: +86 21 6034 8000