Alternative fibers make it possible to diversify raw material flows and reduce dependencies. "It is becoming increasingly important for industry to use materials that are readily available, rapidly renewable, and can be flexibly integrated into existing processes. This is precisely where we come in: with fibers that are not only innovative but can also be used industrially—without compromising on key technical properties such as stability," explains Thomas Strieder, Sales Director at OutNature.

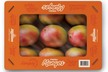

© Hugo Huijbers | FreshPlaza.com

© Hugo Huijbers | FreshPlaza.com

Thomas Strieder (left) and Marcel Petrick presented cup plant packaging for fruit and vegetables at Biofach 2025.

This is more than just a change of material. Strieder: "We are seeing a shift away from linear thinking towards a genuine circular logic. For the packaging industry, this means that environmental impact, resource availability, and security of supply are becoming strategic factors. Companies that start diversifying their raw material base early on will achieve long-term stability, both economically and ecologically."

According to Strieder, users increasingly expect resilient solutions instead of mere promises. They are looking for traceable materials that comply with regulatory requirements and remain available in the long term. "At the same time, there is a growing awareness that packaging is a central part of brand perception. The choice of fiber material is thus becoming a strategic decision." As a manufacturer and supplier of sustainable packaging solutions, OutNature builds bridges between agriculture, material development, and industrial application, according to Strieder. "We show that alternative fibers are not a future scenario but can already be used today. With each project, we demonstrate how cycles can be rethought—in a practical, scalable way and with a focus on the real requirements of industry."

For more information:

Thomas Strieder

OutNature GmbH

Stiftsbergstraße 1

74172 Neckarsulm

T: +49 (0)7132 / 30-773010

[email protected]

www.out-nature.de