There is always pressure on growers and shippers to be more environmentally friendly, lower emissions and carbon footprints, but as in any industry, solutions to these problems must also be financially beneficial, practical, and usable in the growing areas and cold chain.

One of the major challenges facing exporters of fresh produce out of Thailand was the use of polystyrene boxes for transporting products such as baby corn to Europe.

© Coolport Asia

© Coolport Asia

Chris Catto-Smith, Managing Director at Freshport Asia, started working on a solution to remove polystyrene boxes from the Thai fresh produce cool chain many years ago while trying to help recover the UK market for baby corn. Baby corn had always been shipped in polystyrene boxes, but these were no longer acceptable in Europe.

"The solution was a three-way trade-off," explains Chris. "We wanted to remove the polystyrene boxes, while still keeping it viable for the growers and exports, and of course delivering a high-quality product to the retailers."

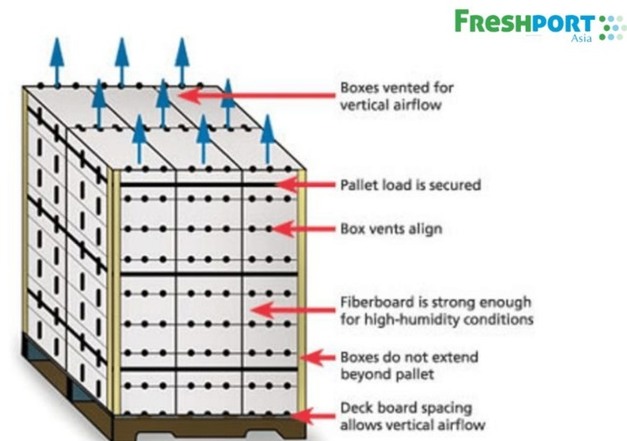

A new solution was presented that eliminated polystyrene usage by replacing it with thermally lined aircraft containers (ULDs), vented cardboard boxes, and precooling before flight, allowing for more efficient shipping capacity and reduced costs for airlines and growers. This solution gave significant environmental benefits, including reduced food waste and fuel consumption, while also giving increased air freight capacity.

© Coolport Asia

© Coolport Asia

"Polystyrene boxes are not efficient for transporting perishable goods as they become heat traps due to inadequate cooling, and the natural heating effect of the fresh produce creates degradation of the product. The polystyrene boxes were also bulky, and the cooling gel packs added extra weight to the loads. Extra weight costs more money spent on transport, inadequate cooling means higher food loss, and lower overall density means less revenue for the airline.

"By carrying out proper pre-cooling procedures at the aircargo terminal and using vented cardboard boxes, temperatures could be reduced and maintained, weight reduced and more product shipped in each container eg. 1,300 kilos fit in one LD.3 container instead of shipper paying a minimum 600 kilos volumetric weight for 450kg of actual product. Esner shipments enabled airlines to charge double for the first container and sell the freed up space for additional containers. This solution creates value for airlines and reduces costs for growers and minimises product damage through proper cooling."

© Coolport Asia

© Coolport Asia

Polystyrene's environmental impact analysis

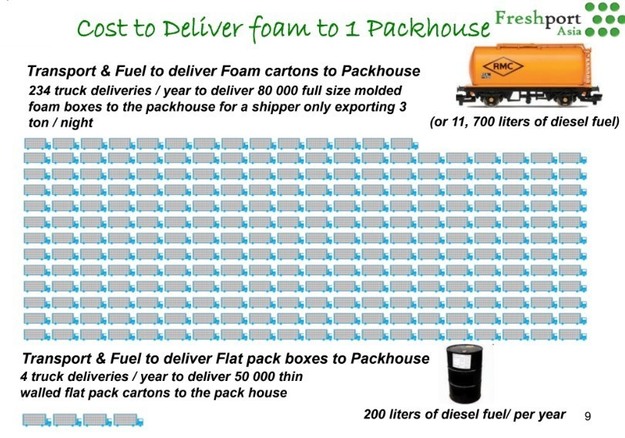

It is not just all about cost saving, though; the environmental impact of polystyrene packaging is huge, it generates significant waste, requires numerous truck movements, and consumes large amounts of fuel. Chris calculated that a single large shipper produces 76 cubic meters of polystyrene waste weekly, leading to substantial landfill and environmental penalties at destination. He also noted that just delivering cardboard packaging from suppliers to the packing houses is more environmentally friendly, requiring only 200 liters of fuel for delivery compared to 11,000 liters for polystyrene boxes.

The polystyrene boxes also had to be disposed of on arrival in the UK, this was a costly exercise.

"We also estimated that Thailand's exports created 40 tons per year of polystyrene waste in the UK, equivalent to a 30-story condominium in volume. By using a cool cargo process, they have eliminated about a million polystyrene boxes since the program commenced.

For more information:

Chris Catto-Smith

FreshPort Asia

[email protected]

www.freshport.asia