As supply chains adapt to Covid-19 social distancing requirements, autonomous reporting technologies like RFID (radio frequency identification) offer a consignment monitoring solution with minimal human intervention. RFID is used to reliably gather temperature data along regular, high volume supply chains and offers the potential to make improvements at predetermined links in the chain.

Manbulloo was the first Australian grower to export R2E2 mangoes directly to mainland China and South Korea. Part of their success is due to cultivating close, trusting relationships with supply chain partners. The ability to retrieve temperature data from the cold chain and share that with supply chain partners has been key to building that trust. The temperature data is critical to making improvements in supply chain practices, building trust and commitment with partners and delivering consistently high-quality product with longer shelf life.

Scott Ledger, Export Manager at Manbulloo said that, with the help of the Serviced Supply Chain team, they started looking for alternatives to USB temperature loggers, mainly because the logger recovery rate was less than 25%. SIM-based loggers were just becoming affordable, but none had approval on airlines with regular flights from Australia. So, they evaluated an RFID temperature monitoring system about 4 years ago. The loggers do not require airline approval, and the autonomous upload of data using communication units overcomes the difficulties of retrieving data from USB devices.

Another benefit of RFID is the automatically generated SMS or email alerts to approved supply chain members notifying of consignment arrival and key consignment information such as a summary of the temperature data and alerts of any temperature deviations outside set limits.

The RFID system requires the placement of the communication units at strategic points in the chain. Scott placed the communication units at the packhouse, the freight forwarder and at the importer in China and South Korea. “We chose these points based on two factors. It’s where temperatures sometimes started going wrong and where we had supply chain partners who could fix the problem if it arose,” said Scott. The RFID system is generally only cost effective for high volume chains where there is repeat business.

Good communication and training with staff is important to ensure correct installation and reliable operation. Over the 4 years, accessing and sharing the data with supply chain partners has increased shelf life of the fruit on arrival at the importer by up to 50% by:

- Ensuring cooling of mangoes down to 13˚C before dispatch from the pack-shed and cutting the time spent at the facility by half. This has included better use of fan-forced cooling.

- Re-cooling of some consignments back down to 13˚C by the freight forwarder

- Requesting importers to adjust holding temperatures when these deviate from the preferred range

Scott said, “All up, this has meant faster movement through the chain at more appropriate temperatures”.

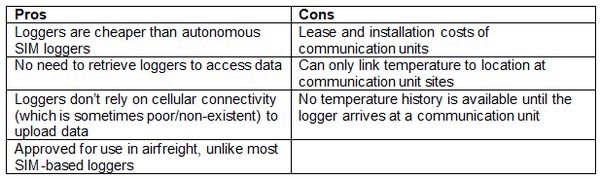

Some of the pros and cons of the RFID system are listed in Table 1.

Table 1- Pros and cons of RFID temperature monitoring systems.

On the right is an example of an RFID logger and communication unit. The logger is placed in the consignment, and the communication unit placed at strategic locations along the supply chain.

On the right is an example of an RFID logger and communication unit. The logger is placed in the consignment, and the communication unit placed at strategic locations along the supply chain.

Some examples of RFID products on the Australian market include Xsense, Sensitech Coldstream RF and Emerson Autosense Inbound. Visit our website for more information on the supply chain innovation research program and access to factsheets on temperature monitoring technologies.

For more information:

John Agnew

Tel: +61 436849357

Email: john.agnew@daf.qld.gov.au