Florida growers turn to CUPS to protect against citrus greening

There are few effective measures, as well as affordable options to thwart the disease on a commercial level. However, some growers have taken a novel approach, as to circumvent the threat all together. Citrus is now being produced in areas of the state, on a commercial level in citrus protective screen structures (CUPS) for fresh fruit production.

This management measure blocks the disease spreading psyllid from contact with the crop. The benefits of eliminating citrus greening from the production equation include normal growth, higher yields, premium-quality fruit, limited fruit drop, and easily managed, nutrient and irrigation requirements. Trees can be grown in the ground or in pots to full maturity within these structures. CUPS are constructed for all sizes, even covering over 100 acres.

With new technology, comes real world adjustments for producers. CUPS will substantially increase the grove budget through construction costs, roughly $1 per square foot. The screen will need to be replaced every 7-10 years, as well. Mites and other smaller insects like thrips will most likely still make their way through the permeable screen, while some of the larger beneficial pest predators are blocked. Fungal diseases like anthracnose and greasy spot may also thrive in the moist, humid conditions of the screen structure.

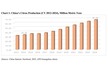

For CUPS production system to be feasible, the construction cost must be offset by the highest yield of premium-quality fresh fruit with a high market price. Florida’s upward trending tangerine market of recent years has been a viable option for this system. Researchers at the UF/ IFAS CUPS facility at Lake Alfred have done extensive study on production units.

Management measures needed for a CUPS operation to succeed are intensive hydroponic practices, with daily or hourly delivery of all essential nutrients by drip fertigation to the trees. High planting densities are needed, with UF/IFAS researchers estimating a range of over 800 and under 1350 trees per acre. Selecting the right tree is key. The variety should be heat-tolerant, self-pollinating, seedless, precocious varieties without strong alternate bearing habits.

CUPS are a new tool against the citrus greening crisis. This solution sounds simple at first, but careful planning is needed for this management measure to be a success.

For more information: Tel: +1 639 3200

Read more at chipleypaper.com