In Belgium, something that began by chance has now been around for 20 years. Father Jan and son Alec van den Heuvel are building a modern family business. Their strength lies not only in their products, but above all in their vision and collaboration, they say.

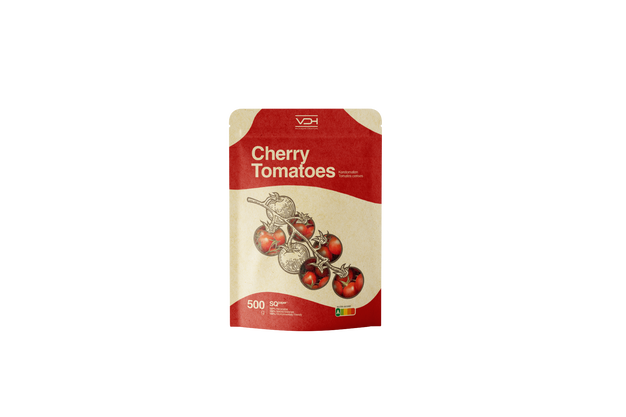

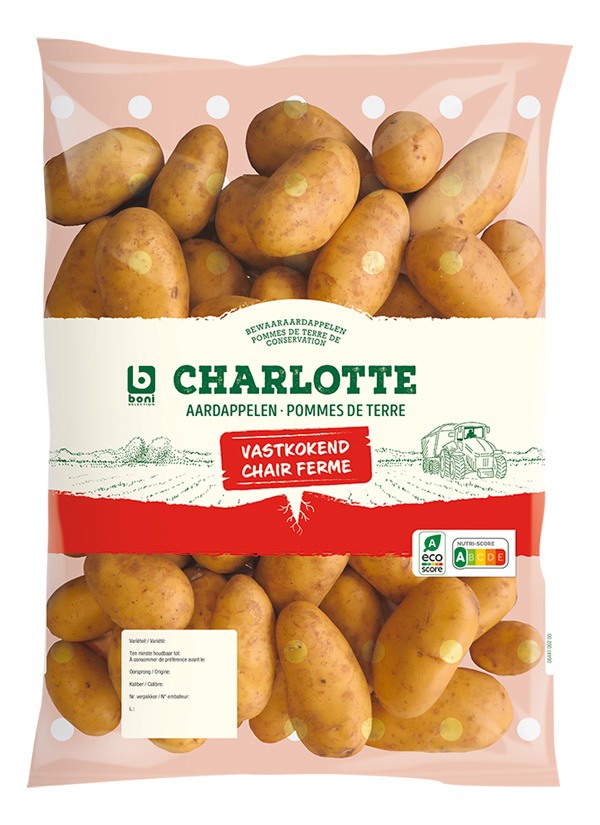

© VDH Packaging

© VDH Packaging

"No two projects are the same. Even if the packaging looks similar, the small details make all the difference. Transparency, clear communication, and daring to tell it like it is—I've carried that with me all these years. Also, our profession is becoming increasingly technical. Continuing to think about the packaging of tomorrow is vital to our livelihood," explains Jan.

From representative to developer

In its early days, VDH primarily served as an agent for packaging manufacturers in the fresh produce market. It soon moved towards in-house development and production, including VDH Polska, which specializes in perforating LDPE and paper. "We've developed our own machine that can perforate mono materials with extreme precision." The company thus evolved from representative to total supplier, with a focus on co-creation and innovation.

© VDH Packaging

© VDH Packaging

Alec joined the business about six years ago, adding a new dimension: Digitization. The switch to an entirely new ERP system significantly boosted efficiency. "Our people can now focus on the essence of our work instead of administration. And we communicate faster with customers, from quotation to support," he says.

© VDH PackagingInterpom 1993 Jan with Minister of Agriculture

© VDH PackagingInterpom 1993 Jan with Minister of Agriculture

These two generations working together are dynamic, sometimes creating friction, but especially being complementary. By now, their roles are clearly defined: Alec runs the day-to-day operations, and Jan focuses on innovation and vision. Together, they determine strategy.

Innovation as driver

From the outset, the need to innovate has been crucial to that strategy. "We combine technology with sustainable raw materials like recyclable mono-laminate paper that can be fully welded, and LDPE based on recyclate or sugar cane."

© VDH Packaging

© VDH Packaging

But, for VDH, sustainability has never been a goal unto itself. "Packaging is only sustainable if it really works. You must guarantee shelf life, processing must run smoothly, and consumers must be able to use it," says Jan.

© VDH Packaging

© VDH Packaging

Alec adds: "We constantly monitor the triangle of technical performance, ecological footprint, and commercial relevance. That's why we prefer involving clients in the development phase, so we can respond more quickly."

© VDH Packaging

© VDH Packaging

These days, VDH supplies the whole of Europe and even beyond, as far as Canada, Australia, and the USA. "It's demanding, but if you keep creating and growing, as a person and a company, it's the best job there is," conclude the two men.

For more information: VDH Concept

VDH Concept

+32(0)368 506 33

[email protected]

www.vdhconcept.com