The apple market is proving to be a steadily growing market. In fact, there is a positive trend in terms of value and quantity. The Italian company PND, specialized in the production and marketing of fruit processing machines, has dedicated an entire line to this delicate fruit.

Daniele Mercurio

Daniele Mercurio

Daniele Mercurio, the new manager for the Polish market, where PND has been present for the past 20 years, explains this in more detail.

"In Poland, our company has as many as 60 customers who recognize PND as their sole supplier of apple processing machinery. Last month, two fully equipped lines were added and installed. The automatic line," says Mercurio, "consists of the group's best-selling PL8 semi-automatic peeling, de-seeding and calibration machine, the ORN8 automatic feeder and the DTF treatment tank.”

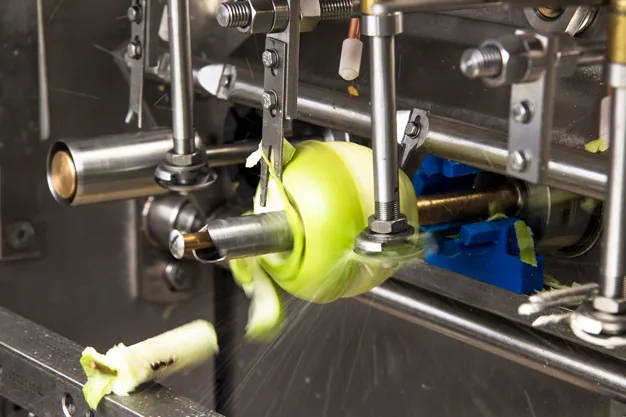

The PND apple peeler is one of the most sold machines. In fact, it can reach an output of 22 to 80 fruits per minute, depending on the needs and the model chosen. Versatile and made of food-grade stainless steel, it ensures minimal operator intervention and can be easily converted to automatic by connecting it to the automatic loader.

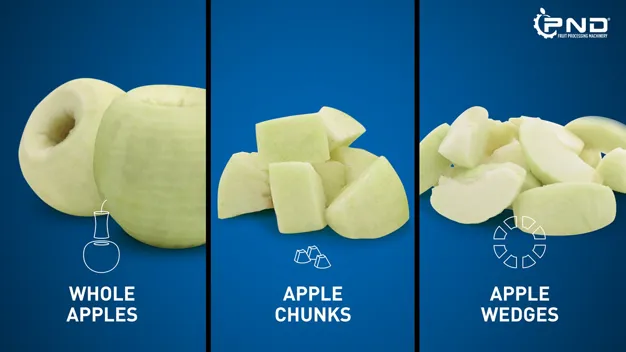

"The PL8 peeler, which is also available in a smaller version with 2, 4 and 6 cutting stations, is one of the most versatile peelers we have in our catalog," continues the manager, "as it can process apples, pears, kiwis and peaches. It ensures precise and gentle processing with minimal operator intervention and is made of food-grade stainless steel. Once the peeling and de-seeding process is complete, the fruit is conveyed into an optional slicing or dicing system.”

These two lines can then be connected to the DTF treatment tank. This is the most effective way to extend shelf life, thanks to the optional conductivity control unit and dosing system. The fruit is immersed in a substance that can extend the shelf life of the product, protect its aroma and color, and avoid the risk of oxidizing. The timing is at the discretion of the customer.

"At PND," concludes Daniele Mercurio, "we have been able to win the trust of our customers, to whom we offer a fast and efficient service that covers all the latitudes of the world, thanks to our experience in the field and the expertise of our specialized staff. We're very satisfied with the exhibition we have just participated in, the Warsaw Food Tech Expo, the last one of the year for us, which took place from the 28th to the 30th of November. This event gave us the opportunity to meet our valued customers and to further consolidate our presence in Poland.”

For more information:

Daniele Mercurio

PND -

Fruit Processing Machinery

Via Brancaccio, 11

84018 Scafati (SA) – Italy

+39 0818509368

[email protected]

www.pndsrl.it