ULMA Packaging will take part in Fruit Logistica 2026, where it will present a range of packaging equipment for fruit and vegetable applications. The company's focus at the event is on machines designed to operate with different material types in response to changing regulatory and waste management requirements.

© Ulma

© Ulma

ULMA Packaging develops packaging equipment compatible with recyclable films, paper-based materials, and other formats intended to reduce material complexity while maintaining line performance. The systems shown are designed to accommodate different materials without major changes to operating conditions.

Trayless flow pack packaging for celery

ULMA Packaging will demonstrate a trayless flow pack application for celery using the SIENNA LS BI machine. The application uses BOPP film, a recyclable monomaterial. The packaging format is intended to protect the product during handling while supporting recyclability. The SIENNA LS BI is designed to process different fruit and vegetable formats with minimal mechanical adjustment. Operating parameters such as bag length, temperature, and speed are controlled electronically. The machine features stainless steel construction and access designed to support routine cleaning and frequent product changes.

© Ulma

© Ulma

Recyclable flow pack packaging for Conference pears

A second flow pack application will show Conference pears packed in a cardboard tray using paper film with a mesh window. This solution is run on the FR 200 flow pack wrapper and is presented as a fully recyclable packaging format. The FR 200 is designed for integration into existing lines and can be used for fruit and vegetables packed with or without trays. It is compatible with recyclable, compostable, and paper-based films.

At this edition, the FR 200 will be shown with the Flex Set system, developed to simplify sealing jaw adjustment when changing between materials of different thicknesses. The system allows operators to carry out changes directly from the machine interface, reducing manual intervention during format changes. © Ulma

© Ulma

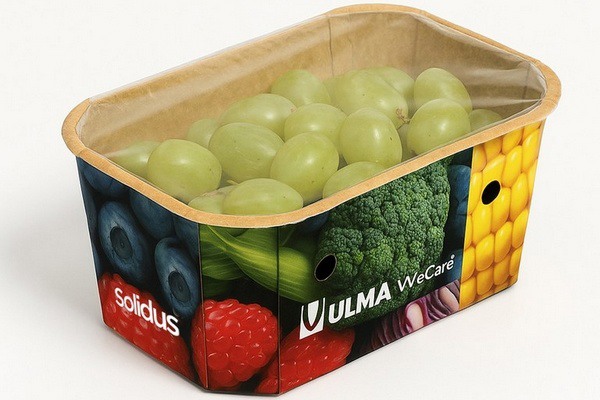

Fruit and vegetable packaging in cardboard trays

For traysealing applications, ULMA Packaging will present a cardboard tray sealed with compostable cellulose film on the TSA 680 P tray sealer. The configuration is intended to reduce plastic use while maintaining sealed-pack functionality. The TSA 680 P is designed for fruit and vegetable lines and can process RPET, cardboard, and compostable trays with recyclable top films. Depending on tray size and format, output can reach up to 150 trays per minute.

© Ulma

© Ulma

Vertical packaging of citrus in paper bags

A vertical packaging application for citrus fruits will be shown using a paper bag with a window, intended for compatibility with paper recycling streams. The application runs on the VTC 840 vertical machine, which is designed to operate with paper-based and plant-based materials. The forming and sealing system is configured to maintain consistent pack quality when processing non-plastic materials.

Digital and control functions

ULMA Packaging will also present equipment features related to data collection and line control. These include real-time monitoring of air, gas, electricity, and film consumption, centralised recipe management across connected machines, and automatic generation of PDF reports covering equipment performance, consumption, and traceability. Data can be stored on the machine or transferred to external systems for further analysis.

Ulma Packaging will be at Fruit Logistica in Hall 1.1, Stand A-10.

© UlmaFor more information:

© UlmaFor more information:

ULMA Packaging

Tel: +34 943 73 92 00

www.ulmapackaging.com