The increasing popularity of strawberries and the significant rise in production come as no surprise. In response to the demand for automation from large-scale producers, PND, an innovative Italian engineering company specializing in fruit processing machinery, has developed automated solutions.

© PND Costruz. Elettromeccaniche

© PND Costruz. Elettromeccaniche

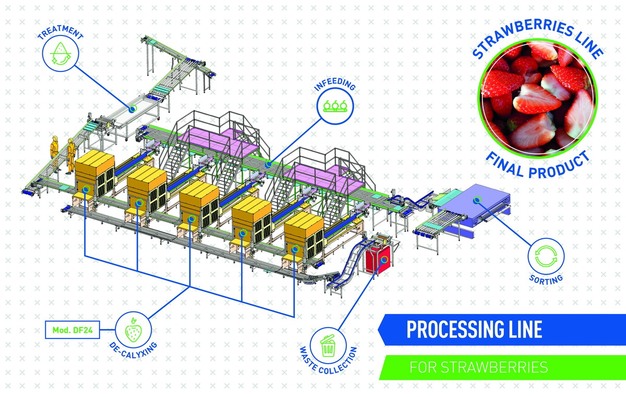

We spoke with Angelo Sicignano, the sales manager. "In terms of consumption, the machines we offer for processing strawberries are performing very well. In fact, demand for these specialized machines is constantly increasing. PND has developed many highly customizable strawberry processing solutions. For example, a fully automated line can include washing, grading, and de-stemming with our DF12 and DF24 models."

© PND Costruz. Elettromeccaniche Angelo Sicignano, PND sales manager

© PND Costruz. Elettromeccaniche Angelo Sicignano, PND sales manager

These machines are designed specifically for strawberries. They are engineered to reduce manual labor and waste while ensuring the careful processing of fresh produce. They remove the green apical part of the strawberry and can cut it in half or quarters upon request, ensuring an excellent yield in a short amount of time without causing mechanical damage. The two main models are similar in many ways but differ in terms of production capacity and labor input. The DF12 can process up to 250 strawberries per minute with four operators or approximately 175 kilograms per hour. The DF24 can process up to 500 strawberries per minute with eight operators or approximately 350 kilograms per hour.

© PND Costruz. Elettromeccaniche

© PND Costruz. Elettromeccaniche

"These machines are made of food-grade stainless steel and feature a rotating 'merry-go-round' conveyor belt that allows operators to load products at any time. They also have an output conveyor belt for drying, freezing, or fresh cutting. The machines can handle strawberries of different diameters simply by replacing the supporting membrane and making minor adjustments to the settings. Processing takes place in three phases: alignment, hulling, and ejection of the fruit. This process can be combined with the cutting phase if the customer requests it. "The product can be processed dry, without the use of water, with minimal waste of around 10 percent," adds Sicignano.

© PND Costruz. Elettromeccaniche

© PND Costruz. Elettromeccaniche

A key advantage worth highlighting is that stalk removal is performed by a rotating blade system that makes a conical cut, removing the calyx without taking away pulp from the peduncular area and preserving the strawberry's natural shape. This is a significant advantage compared to other machines that cut off the entire upper portion of the strawberry collar, reducing yield and altering the fruit's natural form.e fruit's natural form.

© PND Costruz. Elettromeccaniche

© PND Costruz. Elettromeccaniche

"The DF24 model came out over 10 years ago and has been optimized since then. It is a high-performance, complex machine that has received excellent feedback from users. In fact, more than 150 units have been sold worldwide. We are confident that this model, which has already made us proud, will effectively meet the numerous new requests coming in from all over the world," Sicignano concludes.

Customer care is an essential part of the company's approach. Clients are supported throughout the entire process, from design to purchase and commissioning of the machine, regardless of their location. The company has earned the trust of technicians and customers in the industry who recognize its machines as invaluable tools. PND provides personalized assistance and fast, effective service. All wear and tear parts and routine maintenance components are always available, even on short notice.

PND's next trade fair event will be Fruit Logistica in Berlin from 4 to 6 February, Hall 1.1 Stand C-41.

For more information:

PND - Fruit Processing Machinery

Via Brancaccio, 11

84018 Scafati (SA) - Italy

+39 0818509368

[email protected]

www.pndsrl.it