New Zealand machine manufacturer CR Automation works closely with the fruit industry to develop solutions to ensure the fruit adheres to export standards. A solution to the problem of pest contamination which was hampering exports to key markets was found in a high-pressure fruit washer which was a collaboration between Plant and Food Research NZ and the industry and manufactured by CR Automation. The first product released based on this collaboration was in 2012. Since then, CR Automation have continued to refine the technology and now have a suite of fruit washing products for various cleaning specification and fruit types.

More recently the company has developed a new version of the High Pressure Washer to allow higher throughput without reduction in cleaning efficacy.

"We have developed a machine vision option to provide feed-back and optimise the flow through the machine. The additional throughput capacity of the high-speed model allows the high-pressure washers to be sized to match downstream grading equipment in-line, with less installation area and supporting equipment required, allowing for a more affordable investment," said James Buchanan, Sales and Innovation Manager at CR Automation.

"We have several projects underway ahead of the upcoming New Zealand apple packing season and several of our brush pressure washers are installed through Australia processing citrus."

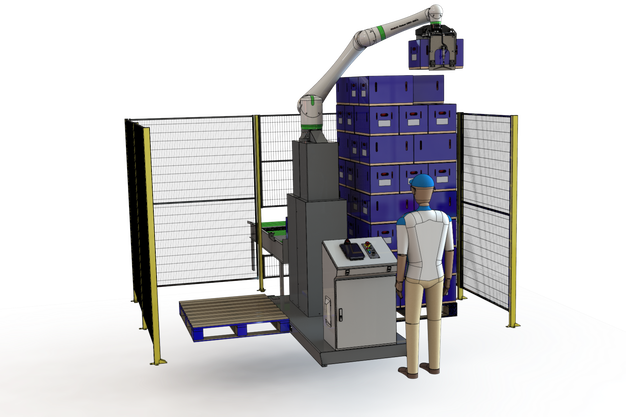

CR Automation have also developed some other new products the Cobot Palletiser, and fibre tray D-Nester.

© CR AutomationCobot Palletiser

© CR AutomationCobot Palletiser

"This was initially designed to meet apple packhouse demands for the gentle handling and stacking of apple Z pack cartons. The Cobot Palletiser is a modular versatile palletising station for up to two concurrent SKUs at up to 300 cartons per hour while occupying minimal floorspace."

The key features include: each cell palletises two pallets simultaneously, the robotic tooling is optimised for telescopic 2-piece cartons, other robotic tooling designs are available on request for crates and varying carton sizes. It can palletise at a rate up to 300 cartons/hour per cell. It has zero pressure DC infeed roller conveyors and is AS/NZS 4024 machine safety compliant.

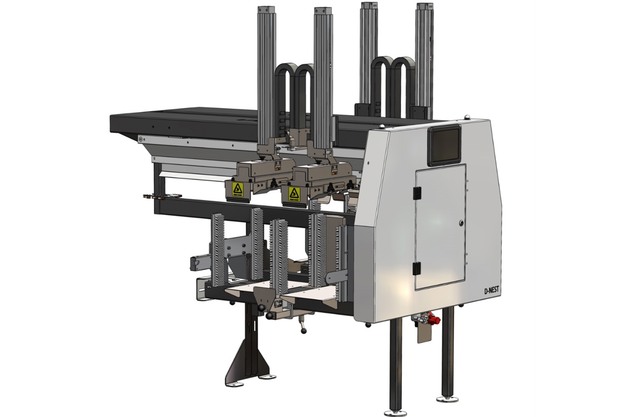

© CR Automation

© CR Automation

D-Nester

"The D-Nester product was developed in a collaboration between CR Automation, Jenkins Freshpac , and a local apple packer, the D-Nest machine is specifically designed to load fibre trays onto conveyors for packing produce. Its main features include: It is fast to load, 14 trays per side per minute, can do a quick change between 50 x 30cm and 60 x 40 trays. It is easy to use with loading of fibre trays at easy working height. Pattern and fault reporting is controlled via integrated HMI or over packhouse SCADA. It is also reliable and designed to handle tightly nested bundles of fibre trays through the unique two stage picking mechanism. The low force and 24 voltage removes the requirement for inhibitive guarding making it very safe."

For more information:

James Buchanan

CR Automation

Tel: +64 6 873 4238

[email protected]