Due to their high moisture, sugar content, and soft texture, tropical fruits have a sensitive nature and provide several processing issues, including separation, maturity management, and quality maintenance. Dragon fruit stands out among these fruits as a perfect example, especially in areas like Southeast Asia where its popularity is on the rise.

According to Maria Vieitez, marketing coordinator of OctoFrost, thanks a number of attractive factors, including its flavor, color and antioxidant content, dragon fruit has attracted a lot of consumer interest. Due to this, the dragon fruit market is anticipated to see rapid expansion, with a predicted Compound Annual expansion Rate (CAGR) of 3.9% from 2022 to 2027.

“We seek to offer thorough insights into the finest procedures required for obtaining the greatest outcomes while processing dragon fruit. Processors can fulfil the rising demand for dragon fruit products and guarantee that their quality is maintained throughout the production process by putting these procedures into place,” Vietez states.

Two elements that are essential for high-quality raw materials

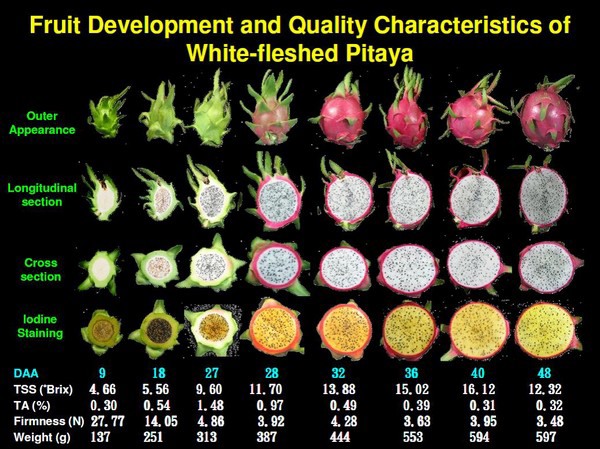

For the production of premium frozen dragon fruit, using high-quality raw materials is essential, Vietez explains: “The fruit's level of ripeness and hardness are two important considerations, since they have a direct impact on the sugar content, which in turn affects the brix level. The concentration of simple sugars like sucrose, glucose, and fructose rises as the fruit ripens, raising the brix level. This influences not just the flavor but also the texture, making it softer and more vulnerable to harm. To guarantee constant flavor and quality, the brix level must be measured, and overripe fruit must be thrown out.”

Achieving desired outcomes also requires managing harvest ripeness, Vietez says. “The intensity of the red color in the peel may be used to gauge harvest ripeness, which is measured by the Days After Anthesis (DAA) period. The ideal brix values for white-fleshed dragon fruit are between 13 and 15, which corresponds to a 32–36 DAA harvest window. For red-fleshed types, brix values between 12 and 13 indicate a harvest window of 27 to 30 DAA. Under-ripeness is indicated by harvesting below the advised DAA levels, while over-ripeness is indicated by harvesting above.”

Optimizing the pre-freezing process to ensure good separation

The choice of the proper processing tools, beginning with cutting and dicing technologies, is the next critical stage in maintaining the look and fresh freshness of the dragon fruit. The quality of the finished product is greatly influenced by the cutting machinery, Vietez emphasizes: “To keep the form, texture, and look of the fruit pieces and avoid bruising, crushing, or ripping, it is crucial to use sharp blades and utilize exact dicing procedures. Additionally, by following this procedure, fruit size and shape are consistent and homogeneous, producing finished goods that are pleasing to the eye. The product should next be thoroughly rinsed to remove any possible particles and loose flesh, and a dewatering device should be used to remove any extra water that may otherwise freeze and cause clumps.”

Cooling is the last pre-freezing stage and can be accomplished with either water or air. Air cooling systems are preferable when working with delicate items, where keeping the quality and shape is crucial, since they permit crust-freezing. Rapid cooling is achieved with this method, which also produces a protective crust that traps moisture and keeps the food's structure while being handled later on, as during IQF freezing or packing procedures.

Extending shelf life with crust freezing technology

Each piece of fruit is quickly and uniformly frozen thanks to crust-freezing, which also aids in even freezing during the IQF process, Vietez explains. “By preserving its quality during storage and lowering the possibility of freezer burn, this process increases the shelf life of the frozen fruit. OctoFrost crust-freezing technology employs a belt with five vibrating thumpers to refine this process and ensure high-quality output by gently shaking the product and preventing sticking and lump formation.”

“In conclusion, choosing premium raw materials, controlling harvest ripeness, and maximizing the pre-freezing procedure are all necessary for processing dragon fruit. These procedures guarantee a constant flavor and texture, maintain the fruit's quality and beauty, and increase its shelf life. Processors can satisfy the demand for dragon fruit products and provide top-notch outcomes by adhering to these best practices,” Vietez concludes.

For more information:

OctoFrost Group

Email: sales@octofrost.com

www.octofrost.com