River Valley Fruit, LLC, a produce grower, packer and shipper based in Grandview, Washington has adopted shelf-life extension technology, Hazel 100, for its cherry packing operations. This simple drop-in solution ensures extended cherry freshness and stems that can remain vibrant green, weeks after harvest – a critical attribute for discerning shoppers.

River Valley Fruit turned to Hazel with the goal of maintaining its cherries' quality and appeal among retailers and consumers, beyond production peak. Following a successful 2021 trial, the quality team was sold. "We use the Hazel 100 sachets in our cherry boxes and have been very pleased with the results. It's extended the life of our cherries easily for four weeks," said Art Varela, quality control manager at River Valley Fruit. "Cherries are highly perishable--within just a matter of days, you can see pitting. By the third or fourth week of using [Hazel 100], there is minimal pitting and minimal brown stems."

The Hazel 100 sachet (center, above) is a drop-in solution that ensures extended cherry freshness and stems that can remain vibrant green, weeks after harvest.

The Hazel 100 sachet (center, above) is a drop-in solution that ensures extended cherry freshness and stems that can remain vibrant green, weeks after harvest.

In previous years, when climate challenges stunted the PNW cherry crop, River Valley Fruit could move boxes as fast as it packed them. Now, facing an unprecedented +50 percent year-over-year supply surge, it and most other growers in the region are reconsidering their postharvest and export strategy.

"We are probably going to have to use a heck of a lot more Hazel 100 because of volume. We're good for about the first week and a half – we can't pack them fast enough, but our volume could slim it back to a week or something, and then we will probably have to start using Hazel," Varela added, highlighting the anticipated need for increased usage of Hazel 100 due to high demand.

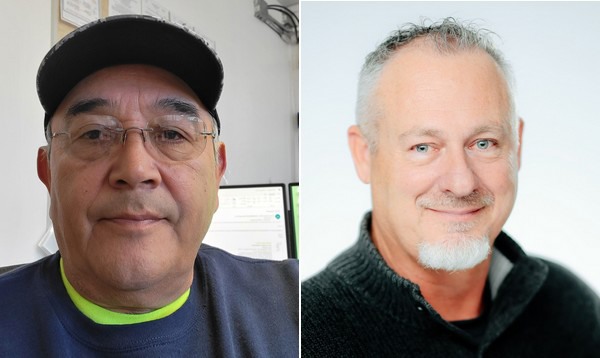

Left to right: Art Varela, Allen Kenoyer

Left to right: Art Varela, Allen Kenoyer

"Art and the River Valley Fruit team have never shied away from embracing new tools that can improve its product. We're so excited about the work we’re doing with cherries and happy to see the impact Hazel will continue to have as it ships its cherries to consumers in the U.S. and abroad," said Allen Kenoyer, Hazel AgTech account executive in the PNW.

For more information:

For more information:

Hazel Technologies

[email protected]

www.hazeltechnologies.com