In order to simplify the exchange of information and to meet the increasing demands in connection with the Supply Chain Sourcing Obligations Act (LkSG), the company Agriplace offers software with which diverse, complex data can be clearly collected and processed by means of automations.

Account Executives DACH from Agriplace Adrian Längle (top left) and Hanna Kirchner (top right) as well as Quality Manager Hildegard Funk (bottom left) and Head of Quality Management Yashar Sarkardeh (bottom right) from Westfalia Fruit.

Introduction to the Supply Chain Sourcing Obligations Act

The LkSG served to protect basic human rights in global supply chains. Compliance with the law was primarily about conducting risk analyses to assess whether human rights were being violated along the chain. The due diligence requirements to be observed include prohibitions on employing school-age children, worst forms of child labor, causing harmful soil degradation, water pollution, etc. This also includes that people must not be deprived of their livelihood.

In Germany, since the beginning of the year, companies with at least 3,000 employees have been specifically affected by this. From January 2024, the law will extend to companies with at least 1,000 employees, including subsidiaries. Companies are obliged to implement risk analyses and appropriate risk management. Previously, companies only had to guarantee compliance but not necessarily make an effort to implement it, Funk said.

"Fuzzy" legal situation

Westfalia is only marginally affected by the LkSG, while one of the company's main customers, food retailers, must explicitly ensure compliance with due diligence requirements and implement their own analyses. At the same time, suppliers such as Westfalia are subject to an obligation to provide information to the food retailer and must implement appropriate control measures if necessary. In the event of violations, the food retailer can demand preventive and remedial measures in this regard.

The existing law was described by the presenters as still quite 'fuzzy'. "Once the law is implemented at EU level, there will also be more clarity. However, more companies will probably be affected by the law such as subsidiaries abroad," Sarkardeh said. Precise control would be difficult measured against the current legal situation. The framework conditions for implementation would still have to be adapted for this purpose.

Agriplace's solution and Westfalia Fruit's customer experience

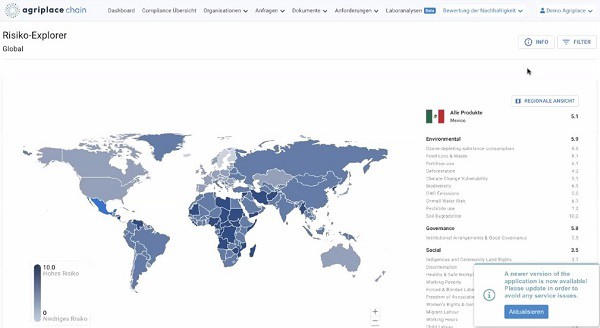

To implement the requirements arising from the LkSG, Agriplace offers software in which all data along the supply chain, such as information about upstream suppliers, is fed into a compliance overview and processed, Längle said. In the next step, the system can be used to directly check which certificates are missing from which suppliers, for example GlobalG.A.P., packaging standards, etc.

In the process, a large number of databases can be accessed via the platform and the data required in each case can be integrated into the system. Furthermore, in addition to the compliance overview, the platform also has a document overview as well as a dashboard with which various requirement regulations are clearly displayed.

An integrated assessment and sustainability module enables both cross-national and regionally different risk assessments. But the system can also present risk assessments of individual products in terms of countries of origin, quantity specifications, etc. "This makes overall risk assessments viewable without having to search multiple databases yourself." The tagging system, which allows users to configure their own categories and adjust them variably, was mentioned as a special feature.

Westfalia Fruit was enthusiastic about the platform Agriplace offers. "If certificates are missing, the system automatically sends out requests to suppliers without us at Westfalia having to proactively contact suppliers ourselves." Data could be retrieved very quickly. The tagging system was also described as "unique" and particularly important, as special requirements that only play a role internally, for example, could also be taken into account. With the risk assessment module, it would also be possible to carry out an assessment within a few minutes and include it in one's own risk assessment.

Further information: Agriplace BV

Agriplace BV

Oostenburgermiddenstraat 206

1018 LL Amsterdam

+ 31 (0) 85 48 97 333

[email protected]

https://www.agriplace.com  Westfalia Fruit GmbH

Westfalia Fruit GmbH

+49 89 72014 184

https://www.westfaliafruit.com