Ethylene for fruit ripening has been used for quite some time. The standard application up until the early 1970s was a ‘lecture bottle’ or ‘tube’, both dangerous and not always effective in initiating the ripening process. It was 1973 and Jerry McDonnell, owner of a banana distribution company, heard of a novel idea of creating ethylene from a liquid.

After investigating, he pioneered the world’s first ethylene generator for fruit ripening, using Ethy-Gen® Concentrate. The system continuously releases small amounts of ethylene throughout a 24-hour application period. Catalytic Generators was born, focusing on a safer and more effective way to apply ethylene. This was different from other ethylene systems in the market that released all their ethylene in one shot and a leak or door opening would result in insufficient ethylene concentrations. Also, at the time some other systems created explosive amounts of ethylene in standard ripening rooms.

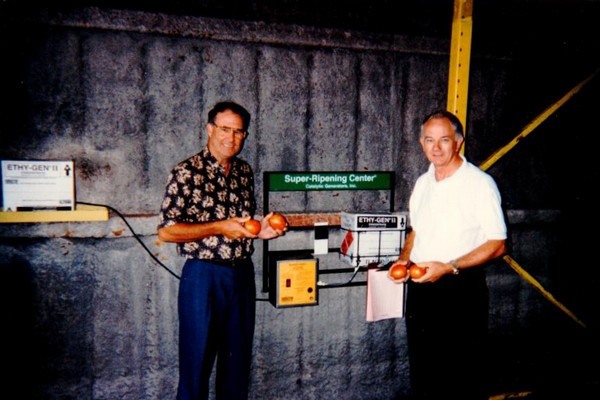

Tomato room in 1995. Right: Gene Akins.

“It was a slow, but steady start 50 years ago,” says Greg Akins, the company’s CEO and President. “As with most new inventions, people were wary of change. However, with the efforts of founder Jerry McDonnell and his new company President Gene Akins, the technology spread rapidly in the 1980s. Gene Akins had joined McDonnell in 1979 and stayed with the company until his retirement last year. In 1995, Gene’s son Greg joined the company as well. “I began my career as a banana ripener, briefly worked in Chiquita’s marketing department, and then managed a tropical fruit distribution company,” Akins said. After ten years, he was offered a position in the sales department of Catalytic Generators. “With tropical fruit ripening experience, it was a great fit it as I knew the challenges that ripeners dealt with. Meeting fellow ripeners and helping with ethylene application was an exciting new adventure, and I haven’t looked back as I love this job.”

The concept of Catalytic’s ethylene generator was a huge change to the banana industry and made the ripening process safer and easier. The invention of the Centralized Ripening System (CRS™) in 2000 generated a major shift for large ripening facilities as it allows them to use multiple generators without manually having to fill the machine. Filling has become an automated process and can be done from one central Ethy-Gen II supply point.

Catalytic's first ethylene generator from 1973 and the latest generator.

Support around the globe

Over the years, Catalytic Generators has their systems in use across the world. “We started in the US and our first endeavors outside of the US were in Canada. Soon, we started partnering with companies experienced in bananas in other countries with Great Britain being the first country outside North America. As we found the right people elsewhere, we could explain the advantages of our systems, enabling us to effectively expand,” said Akins. Today, the company is able to support ripeners all over the world, including North America, Europe, Australia, Brazil, and more.

Regulatory approval

Catalytic differentiates itself by specializing in ethylene only. “It’s all that we do,” said Akins. “Our focus is exclusively on ethylene and providing effective systems to safely introduce them into commercial ripening rooms. Our technical department continues to work on techniques to make the application even better. We are very good at what we do, and work with many fruit companies to give them the systems they want and need.”

In addition, Akins mentioned they are the only company with certification from two independent testing laboratories: UL® and TÜV SÜD. “Also, we have received plant growth regulatory approval in multiple countries and still expanding. The registrations are not easy to obtain, but ensuring a safe working environment for personnel is crucial. Knowing that our systems have been thoroughly vetted by regulators in Europe, the US and elsewhere is a valuable assurance for ripening facilities.”

Last but not least, Catalytic Generators is actively involved with efforts in the EU to ensure ethylene remains a legal and viable source for banana ripening. “This is a costly and strenuous investment, but bananas are too important to health and economies for us not to be involved,” finished Akins.

For more information:

For more information:

Greg Akins

Catalytic Generators

Tel: +1 (757) 855-0191

info@catalyticgenerators.com

www.catalyticgenerators.com