In the shadow of the current Corona issue, the move towards sustainable packaging and the use of monomaterials continues unchanged. According to Torben Ellerbrock, this is also felt by the North German mechanical engineering company AFFELDT Maschinenbau Ltd.

The company mainly supports bulk packers in the bakery, fruit, and agricultural sectors with appropriate counting, weighing, and packaging machines. Now, the company has reached a phase of organic growth, says Ellerbrock. "Recently, mono-materials - such as PE - have been increasingly used on form-fill-seal machines in the Carry Fresh sector. Likewise, there has been a strong increase in demand for paper packaging, which we also produce on our machines. We have already gained some experience in this segment and are pleased to offer our customers well thought-out solutions."

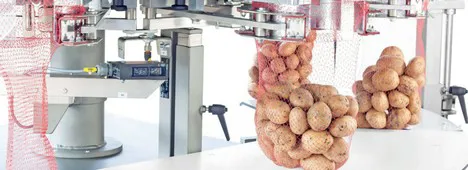

The ultrasonic clipper machine / Image: Affeldt Ltd

The ultrasonic clipper machine / Image: Affeldt Ltd

Future-oriented and competitive solution

Whether for citrus fruits or potatoes and onions, packaging sizes are becoming smaller, according to Ellerbrock. "Due to the changing packaging units as well as the increasing use of mono-products, packers are faced with new challenges in terms of machine equipment. Either existing plant technology is then retooled to meet the new demands, or the decision is made to implement new machines."

In both cases, AFFELDT looks for a future-oriented and competitive solution in close cooperation with the respective packer. Ellerbrock: "It often happens that a complete solution is required, in which we supply both batching, primary packaging and secondary packaging."

Use of renewable raw materials

Last year saw the launch of the ultrasonic clipper, which, unlike proven solutions, does not require a conventional metal clip and processes label and net from identical materials. According to Ellerbrock, the response has been tremendous. "We have received inquiries from all over Europe as well as New Zealand. However, due to different legislation in the countries, the ultrasonic clipper does not arouse interest everywhere. The ultrasonic clipper supports the idea of a circular economy of recyclable packaging made from monomaterials such as PE. However, countries such as France are banning plastic packaging, so the trend there is toward renewable resources."

In view of the impending ban on plastic in France for certain types of vegetables, more solutions are urgently sought, he said. Personal contact and exchange with industry colleagues are all the more important. "On-site appointments are not mandatory, but nevertheless new ideas and approaches often emerge on-site at the customer's premises, or at events."

For more information:

AFFELDT Maschinenbau GmbH

Torben Ellerbrock

Altendeich 14

25335 Neuendorf

Deutschland/Germany

M +49 (172) 1581134

F +49 (4121) 296 - 185

t.ellerbrock@affeldt.com

http://www.affeldt.com