This is a complete solution to create perfectly packed products, whose qualities are fully preserved: we are talking about the weighing, filling and packaging line of the Italian company GNA based in Ozzano dell'Emilia, in the province of Bologna. This line was recently installed also in Iceland.

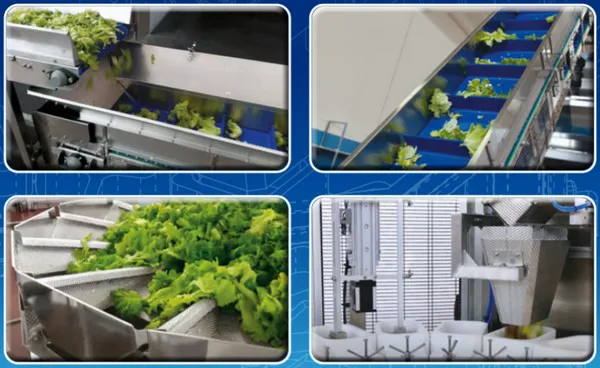

The solution is suitable for several types of products, in particular for lettuce, baby leaf and fresh-cut: it can process even the most sensitive produce in a gentle way and accurately. The line is modular and customizable and can be completed with accessories and specific machines for the desired result.

Among the strengths, GNA emphasizes: the extreme versatility of the line in meeting customer requirements, the extreme compactness and ease of cleaning, the high performance even with difficult products, the lay-out adaptable to the space requirements of the customer and also implementable with the packaging in bags with vertical machine. "In particular, the V80S is the real plus, because it is easily sanitized and user friendly."

"The complete line is an evolution of other similar systems already installed by other customers – explains GNA – It was therefore adapted to the needs of the end-user, with the coordination of the distributor and his request. The line has been installed since last October at the Icelandic end-user and, after the production start-up, has started working on a daily basis".

Magnus Sigurdsson of Multivac ehf, the distributor who supplied GNA's complete weighing, filling and packaging line, said: "Having a single line represents significant cost savings and this was what our customer was looking for. We came across GNA's solutions at last year's Fruit Logistica. Currently, the end-user is very satisfied with the line they purchased."

Mode of operation

The line starts with a sorting belt for selection and check of the product. This is followed by an elevator belt for product transport to the weighing machine. The 14 channels multihead weigher guarantees maximum weighing accuracy. The next step is the denester that prepares the empty trays to be filled.

At this point, the V80S octagonal filling carousel grants precise and gentle filling. A buffering belt controls the transport of the punnets conveyed to the flow pack machine. An automatic synchronization device determines the correct entrance phase of the punnets into the machine infeed and grants a gentle and efficient flow. Finally, there is a Marlin horizontal flow pack packaging machine.

With the introduction of a Bypass belt, the same line can be adapted for the use of a vertical packaging machine such as AV650.

For more informationGNA s.r.l.

Via Progresso, 15 - z.i. Ponte Rizzoli

40064 Ozzano dell'Emilia (BO) - Italy

Phone: +39 051 799226

Fax: +39 051 796962

info@gnasrl.com

www.gnasrl.com