COVID-19 has hugely influenced people and how they live. But it's also affected how things are packaged. "Before the crisis, the trend was to use as little packaging as possible. Now it's more, rather than less, packaging," says Sofie Vandereycken of Belgian packaging specialist Presa. "Many fruits and vegetables are packaged in plastic film again. That's for hygiene reasons. This kind of packaging was a point of discussion before the crisis. But its demand has increased considerably again."

Sofie can only speculate if this trend will continue after the COVID-19 crisis has passed. "I can't see into the future. But I think the increased packaging trend will continue for some time. There's also more interest in mono-material packaging. This packaging consists of only one type of material. It's much easier to recycle than packaging made of multiple materials. So, It's sustainable. This packaging can be either plastic film or paper."

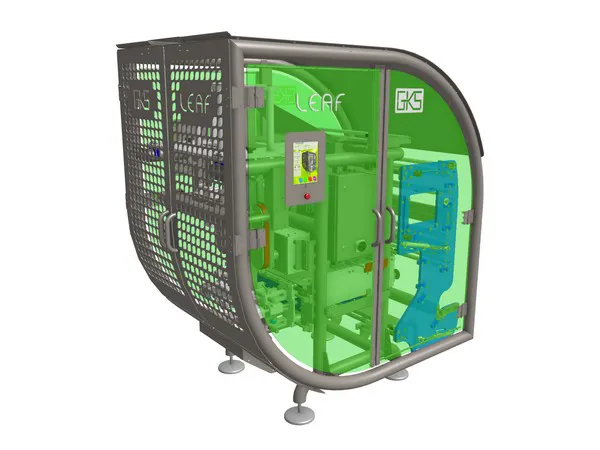

The Leaf vertical flow pack machine.

Leaf vertical flow pack machine

Presa recently added a machine to its assortment - the Leaf series vertical flow pack machine. It seamlessly meets the demand for mono packaging. "The Leaf was designed to produce paper bags. These are made from 100% recyclable, compostable paper mono-material. It uses coated materials. That makes the packaging ideal for potatoes and other root vegetables," explains Sofie. "This machine isn't only stainless steel. Its construction includes recycled materials, too, like plastics cleaned out of the oceans. That helps reduce plastic waste."

Plastic film

“We've invested in paper packaging solutions. But we still offer plastic film packaging solutions too. Paper doesn't have all of plastic's properties. And some products require film. So, we have several machines for this. These can produce a solid package from as little plastic as possible. It's also important to set the machines up in the best possible way. Then we waste as little plastic as possible."

Lasering

A few years ago, many people were laser marking fruit and vegetables. They considered this a good alternative to packaging. This 'labeling' method, however, didn't quite take off. "The start-up costs for lasering are a lot higher than for conventional labeling," adds Vandereycken. "Apart from that, you can't laser all types of fruit and vegetables. Lasering a product mustn't affect its shelf life. If it negatively affects this, food wastage increases, and so, it's not sustainable."

“We offer both film and paper packaging solutions. So, the choice lies with our clients. People are quick to say plastic film isn't sustainable. But, using paper is also sometimes questionable. We, therefore, try to advise our clients as well as possible. It's vital that they, as well as consumers, feel comfortable about a packaging," Sofie concludes.

For more information: Sofie Vandereycken

Sofie Vandereycken

Presa

558 Brusselsesteenweg

3090, Overijse, Belgium

Tel: +32 (0) 265 70 222

Email: marketing@presa.com

Website: www.presa.com