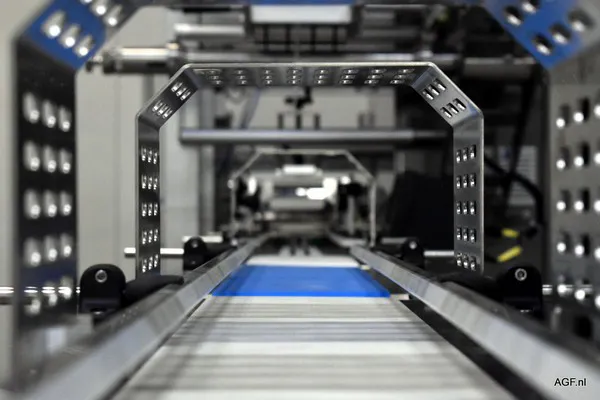

This week Bart Nemegheer of De Aardappelhoeve collected up a new Barsch horizontal flow pack packaging machine. That was from Prins Verpakkingstechniek. These are both Dutch companies. At De Aardappelhoeve, the new machine replaces of an older line. It's used for potatoes in small packaging. It has input/output and Vioprint print&apply systems. Prins Verpakkingstechniek has more than just these machines in its assortment. Some packaging solutions have yet to be discovered by businesses. That includes multi-compartment packaging.

De Aardappelhoeve's knocked on Prins Verpakkingstechniek's door many times. That's when they have new ideas for putting the potatoes on the market. In the past, Prins Verpakkingstechniek, for example, installed part of a packaging line there. That was in collaboration with another Dutch company, Het Packhuys. Prins supplied and installed the transfer system. That went between the weigher and the packing machine.

Broad package

"As packaging specialists, we can offer a wide range of solutions," says Prins Verpakkingstechniek's Sales Manager, Jan Strijbos. " We didn't only do De Aardappelhoeve's flow packer. We're also working on designing a new weigher for pumpkin cubes. Using our expertise, we're supplying the vertical packaging machine. We'll merge it with another company's machine that cubes the pumpkin."

"We can, therefore, offer our clients total solutions. We can easily adapt our own machines if desired too. For instance, we changed the pumpkin blocks machine's transfer system. We expanded the capacity by adding two filling tracks. But, we aimed for a compact machine, so we had to customize it. We can configure our machines in hundreds of ways. With, say, weighing machines, metal detection, etc."

The company not only has a wide range of solutions. It's also the preferred supplier of the German company, Innotech. This manufacturer specializes in vertical packaging lines. "Prins Verpakkingstechniek has a large share in that company. We're a flow packer dealer in the Benelux too. That's for another German company, Barsch, " Jan says.

From plastic to paper

But, Jan sees several challenges in the packaging world. "Vertical packaging is mostly done in plastic packaging. But, there's been a clear shift towards paper as a packaging material for some time now. That involves challenges like adapting a machine. However, thanks to the right types of paper and adapted machines that we have, that's possible."

An example of a compartmented bag

An example of a compartmented bag

Compartmented bags

A less successful item is multi-compartment packaging. "The Spanish company, Irta, specializes in this unusual packaging. You can separate products in one package. We first used these in 2014. A Belgian company wanted to package potatoes of three colors. That was for the [Football] World Cup; to represent the Belgian flag."

"It was more for promotion and didn't do very well." Jan says he, nevertheless, sees future opportunities for this. "This is a packaging with which you can really distinguish yourself in the current market. The technique is there; now we just need the product," he concludes.

For more information: Jan Strijbos

Jan Strijbos

Prins Verpakkingstechniek

35 Stork Street

3905 KX, Veenendaal, NL

Tel +31 (0) 318 565 880

Email: jstrijbos@prinsverpakkingstechniek.nl

Website: www.prinsverpakkingstechniek.nl