This year at the MedFEL, Giuseppe Merloni and his team introduced Paper Bag and Paper Pack to professionals in the sector for the first time: "We wanted to create a paper that would respond to environmental issues and current market expectations, which encourage companies to find alternatives to plastic. The unique aspect of this packaging is that it is 100 % recyclable into paper, compostable and biodegradable.

This year at the MedFEL, Giuseppe Merloni and his team introduced Paper Bag and Paper Pack to professionals in the sector for the first time: "We wanted to create a paper that would respond to environmental issues and current market expectations, which encourage companies to find alternatives to plastic. The unique aspect of this packaging is that it is 100 % recyclable into paper, compostable and biodegradable.

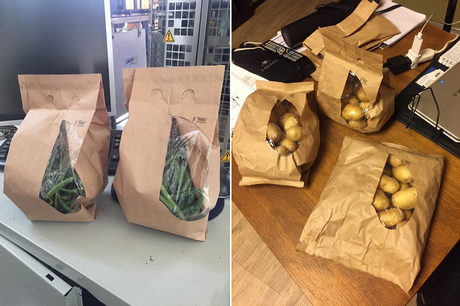

Both packagings are indeed entirely made of kraft paper. Paper Bag is suitable for vertical packaging machines from 500g to 2.5kg and the Paper Pack has been designed for horizontal machines from 250g to 1kg.

Environmentally responsible packaging....

The most interesting feature of these paper packages is the composition of the seal: "Thanks to the No Waste Technology patent, we have succeeded in developing a paper that can be thermally sealed between 150 and 250°C. There are therefore no polluting chemical components. The paper is suitable for food contact and the components that allow soldering degrade naturally in water," says Giuseppe.

There is another interesting aspect to this packaging. It is possible to see, thanks to a transparent cellulose hydrate window, the product they contain: "the window is a component derived from a plant derivative that is completely biodegradable. This does not only pose no environmental pollution problems during product degradation, but also during the paper recycling process. We also have the official Aticelca MC 501-17 class A, A+ certification, which allows us to affirm that paper is recyclable throughout Europe.

This packaging is also rigorously traceable, as the paper needed to create it comes from Scandinavian forests, which are managed in a sustainable way. Giuseppe says he is "proud to say that our product is part of a dynamic of a circular economy".

...which can be adapted to existing packaging machines

"It has been 8 months since we introduced our packaging in our customers factories, in the fruit and vegetable industry. We adjust the machines and perform tests on Ulma, Jasa, Gks, Martini, among others. Another major advantage of our products is that it is not necessary to buy special packaging machines. With some modifications, the machines already on the market are able to package fresh or frozen products with our paper. There is therefore no need for investment and depending on the product in question, the cost of packaging is not noticeably higher.

Not to mention the gain in the shelf life of the packaged product, thanks to the paper which, porous by nature, allows it to breathe, unlike plastic which blocks it if it is not perforated," explains Giuseppe.

Giuseppe will also be at the Macfrut exhibition in Italy to present the Paper Bag and Paper Pack. You can find it on ULMA's booth.

For more information:

Giuseppe Merloni

Phone : +393357220145

E-mail : giuseppemerloni@gmail.com