"Over the last ten to fifteen years, exporters focused mainly on how quickly they could move pallets to market," says Johan Mostert, managing director of DiPAR Systems. "But that's changed: with oversupply becoming more common, the real advantage now lies in ensuring that the right carton lands on the right pallet for the right client."

The recent mandarin season, with its higher-than-normal incidence of peel disorders, illustrates this shift. Producers increasingly need to know which clients tend to claim against a specific defect, what the financial impact has been historically, and whether higher-risk fruit can be identified and rerouted before export.

"This is a deep part of the industry," he says. "It's incredibly difficult to systematize, and very few have attempted it at the scale we're working at."

For DiPAR Systems, it has taken the form of an extensive, multi-year rewrite of all their agricultural software modules, a project now more than 300,000 logged hours deep, expected to reach roughly half a million hours once every module is completed. He explains that the rewrite began in earnest in 2018 to consolidate legacy systems, eliminate duplication, and bring the entire platform up to modern architectural standards.

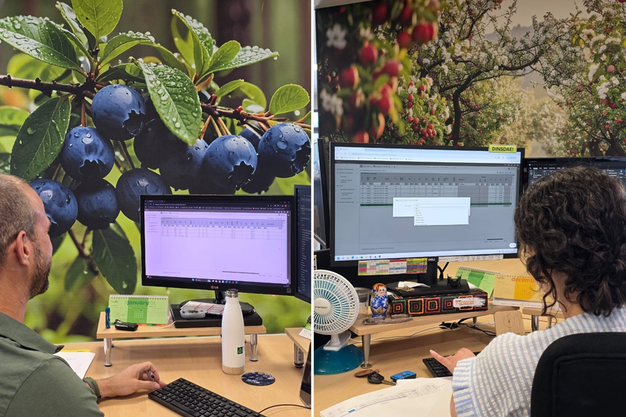

© DiPAR Systems Six33 Produce has been running five farms and a pack house for seven years on a single, integrated DataGear® database

© DiPAR Systems Six33 Produce has been running five farms and a pack house for seven years on a single, integrated DataGear® database

DiPAR has been supplying software to packhouses since 2004 and exporters since 1998, later adding quality control, variety evaluation, labour, and wage-tracking components at the industry's request. They estimate that in some form or other, 20% to 25% of South Africa's fruit goes through DiPAR's products; the exact market share is hard to measure.

The new unified platform is called DataGear®, and alongside the major structural modules, it includes new additions such as a forex management component. To support training, Johan and the DiPAR team used modern AI tools to create an internal training assistant, helping DiPAR's Client Success Team to master and then teach the module efficiently.

"When all modules are complete, this will rank among the largest privately funded Agri-ERP rebuilds in South Africa," he says. Each module is released first to select early-adopter clients for user acceptance testing. Commercialisation then begins with a small group to allow rapid feedback during stabilisation. Once the module is fully stable, broader client onboarding begins as part of a phased migration.

© DiPAR SystemsExporters at Core Fruit using the latest Stock Planning and Allocations module in DataGear®

© DiPAR SystemsExporters at Core Fruit using the latest Stock Planning and Allocations module in DataGear®

From complexity to intelligence

A growing trend in the fruit sector is the use of deep technical data to reduce risk and improve decision-making. DiPAR is leaning into this movement.

One example is cross-referencing specific defects with the historical claims of particular clients, giving exporters a clearer view of risk profiles before they pack a single pallet. For growers, the system can quantify how much a specific defect has cost the farm over multiple seasons, insight previously nearly impossible to extract quickly or consistently.

Food-safety risks can be modelled similarly, and several clients have already used the platform to run mock recalls.

"Our systems collect and track data from pre-commercial variety trials right through to export," Mostert says. "Once DataGear® has been completed, this end-to-end integration will be available in a single, modular system. For inspection agencies, DataGear® feels like a dedicated inspection tool, yet quality control represents only a small portion of the full platform."

As vertically integrated producers and exporters adopt more modules, the depth of benchmarking becomes significant. "The system can measure operational aspects previously difficult to quantify, for instance pruning efficiencies, labour performance, varietal behaviour, scouting intelligence and a range of encompassing metrics that influence decisions and therefore the final packouts and grower returns."

Built in Africa, designed for the world © DiPAR SystemsThe expansion of blueberries in Zimbabwe gave DiPAR a foothold in the broader Southern Africa, where large farms are being established at a pace. Due to exchange rate differences, DiPAR's offering is often substantially more affordable than competing systems, and crucially, the mobile apps are designed to operate fully offline.

© DiPAR SystemsThe expansion of blueberries in Zimbabwe gave DiPAR a foothold in the broader Southern Africa, where large farms are being established at a pace. Due to exchange rate differences, DiPAR's offering is often substantially more affordable than competing systems, and crucially, the mobile apps are designed to operate fully offline.

Right: The Pest Monitoring module in DataGear® in use at Six33 Produce's LeArc Farm, Western Cape

"Six33 Produce is in the process of finishing off their seventh season running five farms and a pack house on a single, integrated DataGear® database," he notes. "They have generated up to 100,000 lines of data in a single day on the app."

Where connectivity is limited, a daily reality on many farms, DataGear® continues to function without interruption. Some clients also make use of optional offline biometric validation to confirm worker attendance. The system allocates duties, integrates directly with harvesting scales, and feeds the resulting data into labour and wage modules in near real-time.

Despite touching several points of the payroll workflow, DiPAR intentionally avoids the accounting-software space. "We've seen farms running three different payroll systems. Our goal isn't to replace them, but to provide the overarching system that connects everything."

Safety, audits and future vision

Audits across the value chain, covering farm, packhouse, export, food safety, and more, are increasingly intertwined. This creates a strong need for cross-modular integration so that compliance, traceability, and risk information aren't trapped in separate systems.

The long-term vision for DataGear® includes additional safety features, such as enforcing post-spray re-entry intervals to prevent accidental exposure for workers, a real challenge in certain crop environments. Similarly, DataGear® aims to integrate receiver requirements, market specifications, consumer preferences, and grower exposure into every allocation decision, with the long-term goal of maximising grower returns while reducing risk.

Among the largest releases, currently in the initial commercialisation phase, is the Stock Planning & Allocations module which is running live at Core Fruit and the Estimates & Planning module which is running live at EXSA and Core Fruit. "Both of these modules represent comprehensive coverage and client configurability, whilst addressing some of the most technically demanding areas of export operations."

© DiPAR SystemsEXSA uses the Estimates & Planning module in their operations

© DiPAR SystemsEXSA uses the Estimates & Planning module in their operations

For more information:

Johan Mostert

DiPAR Systems

Tel: +27 82 940 9820

Email: [email protected] | [email protected]

www.dipar.co.za