A Long Island high school is running one of the most technically demanding educational CEA labs in the region, combining full-scale production with student-designed automation, fertigation control, and crop trials. The result is a space that produces hundreds of pounds of leafy greens each year, while also serving as an entry point into engineering, horticulture, and data science.

The AgTech Lab at Half Hollow Hills High School East began as a small DIY project in 2017. What started with buckets and improvised fittings has grown into a controlled environment programme anchored by commercial NFT units, high-intensity lighting, automated irrigation lines, and a student-built IoT monitoring system. The lab donates its harvests to a Long Island food pantry through a partnership with Island Harvest.

Chris Regini, the engineering teacher who leads the programme, says the decision to run real production equipment has shaped both the curriculum and the students' expectations. "The AMHydro NFT units have performed very well for lettuce and herbs," says Regini. "Students must still manually refill the reservoirs and ensure there is appropriate flow in each of the 60 NFT channels. When mature crops undergo rapid evapotranspiration, levels drop fast. Our sensors will shut down the pumps to keep them from burning out, but that does not protect the crops. We have to act quickly to bring circulation back online." © Chris ReginiVertical NFT production towers with custom lighting and fertigation systems

© Chris ReginiVertical NFT production towers with custom lighting and fertigation systems

Lighting, airflow, and crop trials

Each of the two NFT towers is outfitted with Bios Icarus Vi fixtures. Every tower contains three tiers, and every tier is lit by three full-spectrum lamps mounted roughly 24 inches above the canopy. The fixtures draw 600 watts and deliver a PPF of 1320 micromoles per second.

"The crops run on a 16-hour photoperiod," Regini explains. "The lighting in the production towers stays fairly consistent, but we have separate experimental stations where students test different spectra and durations. They use Apogee PAR meters to take readings and compare results."

This autumn, the lab trialled six lettuce varieties side by side. Oakleaf and butterhead produced softer textures but weighed significantly less than romaine. "If we run a full cycle of romaine, we can harvest roughly 225 pounds in one cycle," says Regini. A school year allows for eight to ten cycles, depending on the academic calendar.

Everything grown to date has gone directly to a local food pantry. Island Harvest supplies seeds, growing media, and packaging materials, and receives weight reports for every donation. Regini says the next phase is to bring some of the produce into the school meal programme. © Chris Regini

© Chris Regini

A shipment of greens harvested by students awaits collection by a local food pantry

Automated fertigation and the custom "Red Hawk" system

The lab relies on two-part nutrient formulations supplemented with CalMag, mixed into stock solutions on site. "Given the lower nutrient needs of lettuces and herbs, we find this is enough," says Regini. "Other water chemistry, such as pH and ORP, is automated by our custom fertigation lines. Atlas Scientific probes read the target values, and the peristaltic pumps reestablish the setpoints."

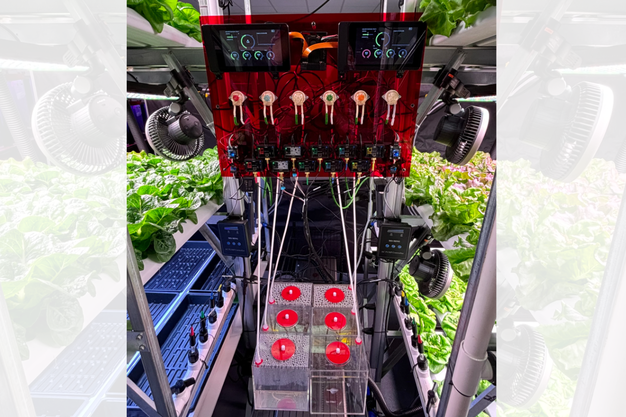

Additional sensors track temperature, dissolved oxygen, and flow rates as redundancies to ensure pumps and chillers work as expected. The heart of this control network is the "Red Hawk" monitoring station, built and coded by students. "It is housed on a custom panel that we laser cut on site," Regini says. "It leverages Atlas Scientific EZO sensors for data collection. Python programs serve these data points to an online dashboard we designed using Adafruit IO. Students learn how IoT systems function by breaking out the components into smaller lab challenges."

One activity teaches students to trigger a relay with a moisture sensor. Another has them programme a pump to dispense a specific volume of fluid after a pH threshold is reached.

"Students should be able to look at any control system in the lab and have a functional understanding of how it works," says Regini. © Chris Regini

© Chris Regini

A custom-made monitoring system named "Red Hawk" has been programmed, laser cut, and assembled on-site

Managing environmental conditions during school breaks

AC Infinity tools manage airflow and environmental stability when students are off campus.

"One of my favourite features is the ability to set circulation fans to dynamically change their speeds to simulate the types of wind conditions crops may experience in the field."

Water management remains the most difficult challenge. Mature crops require frequent top-offs, and the school calendar prevents the team from running large cycles across long weekends or holiday breaks. Regini hopes to automate reservoir refills in the future.

A CEA learning space backed by research partners

The technical work feeds directly into the academic side. The lab participates in citizen science programmes, NASA engineering challenges, and plant science research activities. Students collaborate with Brookhaven National Laboratory to build a scientific computing curriculum that uses real farm data for programming, visualization, and modelling. They also work with the Danforth Plant Science Center on computer vision activities for plant health analysis.

"We are still experimenting with creative ways to incorporate CEA into the STEM experiences of our students. Independent research projects have already grown out of the lab." Several students have used their experience in the lab to support applications to engineering programmes. The lab has not been running long enough to see the impact on career choices, but Regini expects that to come. © Chris Regini Students use Raspberry Pi to design their own pH adjustment system

© Chris Regini Students use Raspberry Pi to design their own pH adjustment system

Building a talent pipeline for controlled environment agriculture

Regini views the lab as a place where students can acquire skills that will be valuable to the CEA industry. "I would love to establish a standalone course dedicated to CEA eventually," he says. "In the meantime, I am always looking for opportunities to learn and collaborate with industry professionals, university researchers, and technology producers. It would be amazing if our space could serve as an innovation lab where students can learn how to apply cutting-edge skills supported by partnerships with those looking to vet equipment or procedures."

He adds that the responsibility of training the future workforce is not lost on him. "I believe the space is an incubator for the CEA industry. Those who will make the greatest strides in this field sit in front of me every day." © Chris Regini

© Chris Regini

For more information:

Half Hollow Hills High School East

Chris Regini, NYS Master Science and Engineering Teacher

[email protected]

www.hhh.k12.ny.us/high-school-east-home

www.reginiusscience.com