"We  © Orbem are creating a 3D digital twin of the product and slicing through it and identifying all kinds of internal characteristics that are of interest to our customer," explains Johann Steinert, Director of New Markets with Orbem, the use of MRI technology for scanning the internal quality of fresh produce.

© Orbem are creating a 3D digital twin of the product and slicing through it and identifying all kinds of internal characteristics that are of interest to our customer," explains Johann Steinert, Director of New Markets with Orbem, the use of MRI technology for scanning the internal quality of fresh produce.

"The MRI technology is well known from medical applications and has been around for some 40 years already. We have industrialised the technology by making it extremely fast and thereby also cheaper so that on a per-scan basis it becomes affordable."

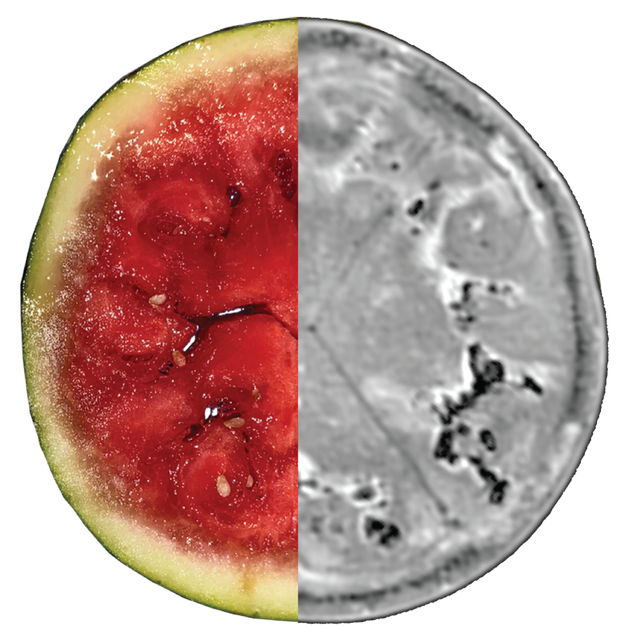

The speed of the technology ensures a high throughput, a very important aspect, according to Johann. "We have to keep up with the industrial volumes that are being processed in the factory. Our technology does not provide value to the customers if it slows down production." Johann explains that for watermelons, a project that is currently being developed, some 20,000 kilograms per hour can be processed. "If the average watermelon weighs 5 kilograms, that means roughly 4,000 fruits per hour, which is in line with the industrial processing standard of a large factory."

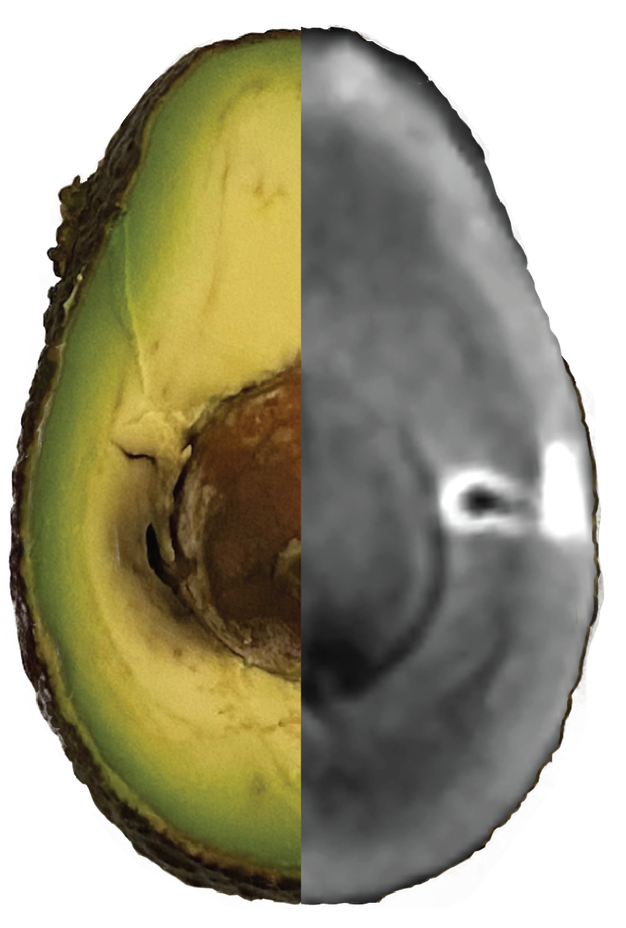

© OrbemAvocado defect and scan

© OrbemAvocado defect and scan

Fully automated

The sorting is done by the system, based on the MRI scans, mentions Johann. "That means that none of our customers have to look at MRI scans and make assessments. Together with our customers, we define what a defect looks like and train our AI models accordingly. We can visualise, for instance, bruising, mold, or internal browning, but also different stages of firmness and ripeness of a fruit. The whole process from start to finish is automated."

Orbem, which is located in Munich, started about 5 years ago and introduced the MRI technology three years ago in the poultry industry. "The technology is used to determine the sex of the chicken embryo while it is still in the egg." Currently, the Orbem team consists of around 200 people, and 25 installations are operational. "We have found that the technology is not only applicable in the poultry industry. MRI can very well visualise soft tissues that contain a lot of water. So, in fresh produce, it will work across a variety of fruits and vegetables."

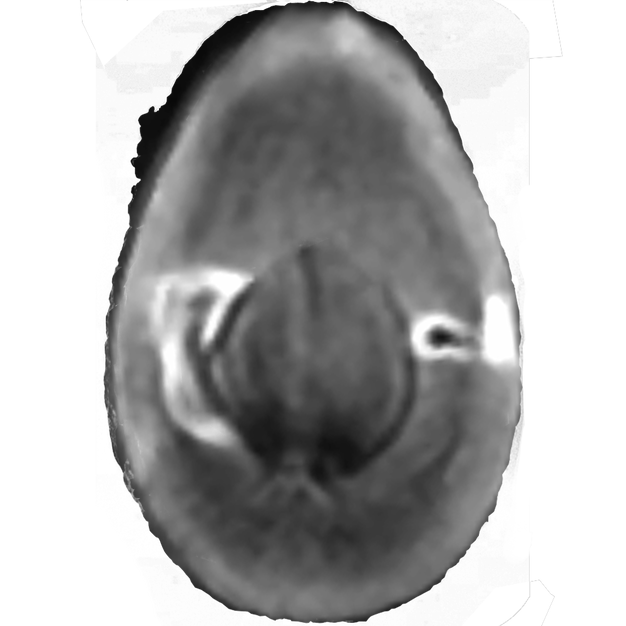

© OrbemAvocado defect scan

© OrbemAvocado defect scan

Adaptable

What does it take to adapt the technology to a new product? It is very adaptable, says Johann. "We have to train the AI models. We do that here in the lab in Munich. If we scan a few hundred samples, that gives us enough accuracy to already create the value that the customer expects." The manager explains that the system gets better and faster the longer it is used. "The more data the model has, the better and faster it gets. Of course, the moment you install your system in an industrial production, you get tons of data every single day. And this is when our algorithms improve quickly. Our current settings in the poultry industry are between 95 and 98 percent accuracy."

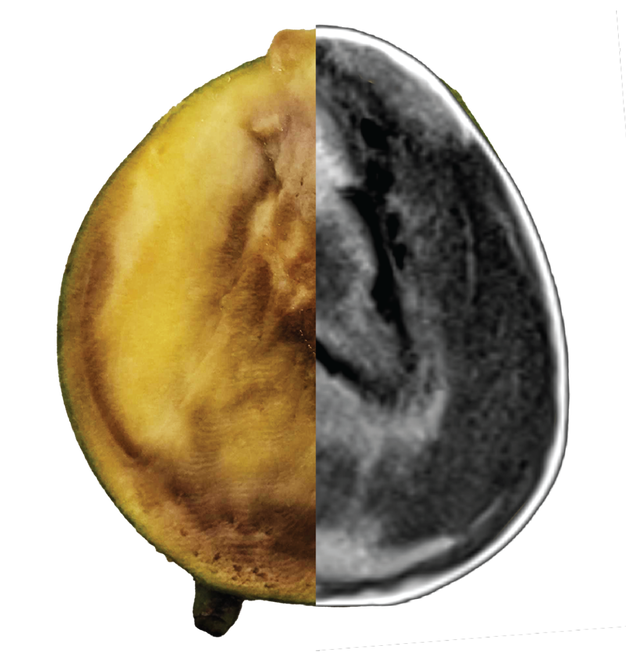

© OrbemMango defect and scan

© OrbemMango defect and scan

Following the application in the poultry industry, Orbem is now adapting the technology for watermelons, and avocados are next in line. Johann explains that the current way to judge the internal quality of an avocado is by slicing it open. "That is how it is done in the whole supply chain, from the grower to the supermarket. If defects are found, new samples are kept sliced open, sometimes up to 10 percent of a batch, which then goes to waste. With the use of MRI technology, we can avoid that."

Consistent quality

Another advantage will be a more consistent product quality. "If you can ensure that you can deliver consistent quality to your customers, that is something that really pays off. For the producers, but also for the whole supply chain. Because in the end, the avocados in the supermarket are always a lottery; you never know whether it is good or bad. Too often, you slice open one that is not good, and it then goes to waste. We want to work on increasing the trust throughout the supply chain because then it is possible to even further reduce waste and improve the efficiency in the food production."

© OrbemWatermelon slices diagonal

© OrbemWatermelon slices diagonal

Not only does the use of the technology prevent waste, but Johann sees that it also impacts the need for labour. "For instance, watermelons are either sliced open or you need highly trained staff that taps the watermelon and can tell by its sound whether it has an internal defect or not - labour shortages make this an increasingly difficult quality check to perform as well."

© Orbem

© Orbem

Orbem does not sell its technology but rather charges its customers a fee per scan or per kilogram, says Johann. "MRI technology is not cheap, but distributing the costs over multiple years and a large volume of production makes it affordable. The question we always ask ourselves is: do we provide enough value? In poultry, watermelon, and now avocados, that is the case: We can offer MRI scanning at a price that is doable for the customer. Also, in mango, we have had valuable discussions, and I think there are possibilities for berries as well."

For more information

For more information

Johann Steinert

Orbem

[email protected]

[email protected]

www.orbem.ai