Located in South Africa’s Eastern Cape province, Sitrusrand, started as a 10-hectare mixed farm now stretches for 60 kilometers along the Sundays River. It has 1,400 hectares dedicated to citrus fruits which the business packs itself.

Employing 1,500 people, Sitrusrand exports citrus fruit to many countries. International sales have been built on a reputation for continuous supply and consistent product quality.

Sitrusrand has expanded massively since Pieter Nortje joined his father at the business in 1994. “Fortune favors the brave,” says Pieter, “and I always knew I wanted to farm on a bigger scale. I bought more farms and by travelling the world I was able to see the needs of different markets. It became my strategy to be able to supply supermarkets with a continuous presence of our fruit, and of the same quality.”

Within a year Pieter joining the business, he had decided to build the farm’s first packhouse. This, he admits, “was a bit primitive. I was spending every single minute of the day in there, and I remember how tough it was sorting fruit by hand, making decisions between four classes of fruit. So I looked at packhouses in Europe with the latest technology. Then, when it became financially viable, we fitted the latest equipment. Through mechanical sorting it became possible to eliminate human error. Now the quality decisions were made instantly by computer and we were in full control of quality settings. Optical sorting made it possible for us to pack the same quality into a carton, and to adapt to market requirements, whether it’s packing better quality or lesser quality. Also, these days food safety is paramount worldwide, and our ability to pack fruit with lower or zero residues has given us a competitive edge. We can guarantee our customers what’s in the carton, and through that we’ve been able to create a brand.”

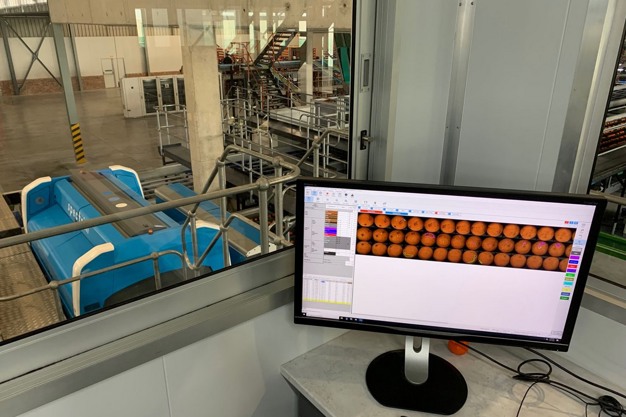

As Sitrusrand grew, Pieter opened a second packhouse, then a third. This made it possible to dedicate one packhouse exclusively to oranges, another to lemons, and another to soft citrus. But still production grew faster than packing capacity – and so, in 2020, the business opened its fourth packhouse. This is equipped with TOMRA’s Spectrim sorter and grader, plus the Inspectra² platform for internal defect grading.

The Spectrim and Inspectra sorting and grading platforms

You need the best equipment to get the best results,” says Pieter, “and with Spectrim and Inspectra², that’s what we’ve got. These machines have opened up new opportunities - especially the brix grading with Inspectra².”

The Inspectra² platform for internal defect grading utilizes a near-infrared spectrometer, mainly to detect brix, but also to provide valuable information about other properties important to citrus growers and packers.

For more information:

Marijke Bellemans

TOMRA

Tel: +32 (0)476 74 19 18

Email: [email protected]

www.tomra.com/food