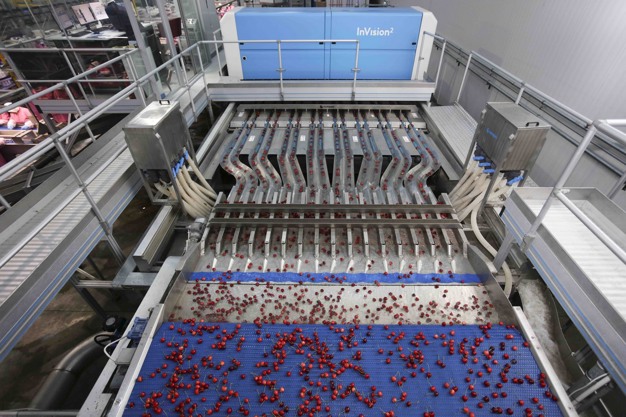

As one Turkey’s top five exporters of fresh fruit and vegetables, Perla Fruit, made a rapid entry into cherry exports when it invested US $10 million in new operations in Bursa, in the northwest of Türkiye, in 2019. The company first began packing cherry products there in 2020, achieving high quality and high capacity with the 16-lane Tomra InVision2 optical sorting and grading platform.

By taking this step forward, Perla has built on two generations of experience as a family business which started with the export of fresh figs in 1986. Today, Perla Fruit's fruit production is 30% cherries, 30% figs, 25% tomatoes, and 15% other products such as blueberries, pomegranates, nectarines, apricots, and peaches. They produce 15,000 tons of fruit and vegetables annually, including 5,000 tons of cherries for export and 2,000 tons for the domestic market.

Perla Fruit’s Board Chairman, Kerim Taner, says: “With the Tomra machine we purchased in 2020, our goal is to double our cherry processing and packaging capacity in three years. We plan to become Turkey's leading export company in cherries, as in figs. Moving towards this goal, we do not compromise our corporate values of quality, safety, and sustainability.

“Perla Fruit has become a robust and reliable brand for fresh fruit and vegetables in both domestic and foreign markets in a short amount of time, but of course, this is not by chance. Years of family experience, the knowledge of our managers and our entire team, and investing in the right technology have paved the way for success. The contribution of our machine infrastructure, from our integrated solution partners Tomra Food and ICOEL, is vitally important.”

Before investing in Tomra equipment, Perla Fruit assessed feasibility by visiting cherry packaging facilities in Turkey, Chile and the United States. Taner remembers: “During these visits we were very impressed by the success and accuracy of Tomra's grading and sorting solutions and the high quantity provided without compromising on quality. It was essential for us to invest in the right optical sorting and grading machines to be a powerful player in even the most demanding markets.

“We prefer to work with customers who embrace the value of our brand. For this reason, we have customers in our portfolio focused on quality rather than price. We sell 70% of our cherry products to Germany, 10% to Scandinavia, 10% to the Far East, and 10% to other European countries. Germany is one of the most challenging and demanding markets, with acceptance rates below those of other European nations, and the Far East is as sensitive. But with the Tomra grading machine we are able to offer a risky product such as cherries to even the most demanding markets in high quality and high volumes. Tomra's contribution to the trustworthiness of the Perla Fruit brand is enormous.”

For more information:

Michelle Haynes

TOMRA Food

Tel.: +64 21 377 141

Email: michelle.haynes@tomra.com

www.tomra.com