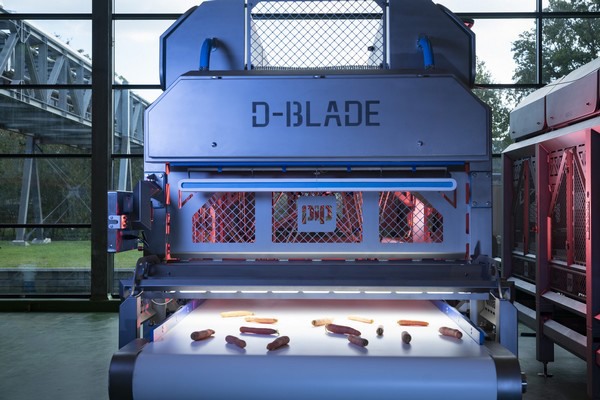

"We’re well-positioned regarding what the market needs: robotizing the cutting process," begins Jeroen Pannekoek, PIP Innovations' Managing Director. This Dutch company focuses on robotized processing solutions for the fruit and vegetable sector. A major U.S. potato chip manufacturer, for example, uses PIP Innovations' technology. Several potato, carrot, and strawberry machines are in place throughout Europe and the U.S., too. "For the global AGF sector, D-Blade is a first for the global fruit and vegetable sector; in this form, it's brand new technology."

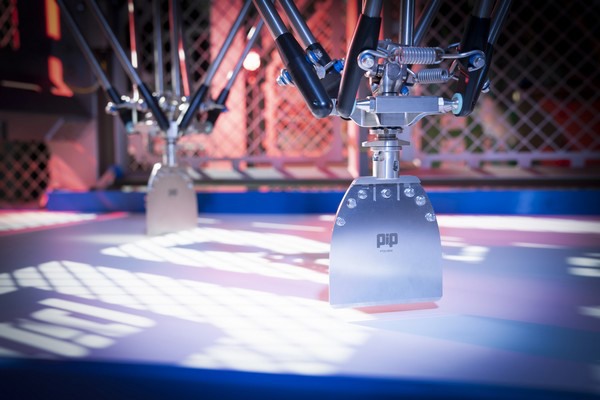

In 2015 - born of a desire to reduce waste due to black dots on sliced potatoes - Bart Kroef, Peka Kroef's co-owner, designed the D-Blade, which precisely cut out those spots. "We merged several techniques. We adapted Delta robots usually used on a factory's 'dry' side for use on the 'wet' side. We replaced the existing grippers with blades and added vision technology, as used in optical sorters," he says. Jeroen compares the machine to a human being. "Its eyes - the vision technology is on its front. Then you have the arms; that's the robots, and because it can't walk, we added a conveyor belt."

Cutting in the desired spot

Jeroen says developments continue at Peka Kroef, where three machines - that save 30 million kgs of potatoes annually - have been placed. That is one of the D-Blade's advantages: yield improvement. But the quality of the cut also plays a role, he points out. "With mechanically cutting, say, a carrot, it's impossible to always cut exactly equal pieces. Plus, the cut will soon lead to damage. We can see the carrot and exactly where the head is," he explains.

"You can remove it and cut the carrot into equal pieces at the same. We can cut in exactly the desired spot. For example, winter and baby carrots, all of the same length." Jeroen reveals that the D-Blade offers room for product innovation because, by replacing the blades, the machine can easily be used for other or new applications. "The D-Blade can do a lot, as long as we can see the product well and cut it from the top," he continues.

Since then, the D-Blade has been further developed for new uses in potatoes: for instance, halving or quartering potatoes, dynamic portioning, and producing Hasselback potatoes. An application for carrots followed, and PIP Innovations was born. The company has its sights mainly on the fruit and vegetable sector, focusing on vegetables because that segment requires a lot of manual labor. Jeroen says that is important because robotizing slicing operations not only replaces labor but also eliminates the need for machine supervision.

De-crowning strawberries

Labor-saving was one of the main aspects of the recent application of D-Blade technology: de-crowning strawberries. Jeroen explains this enormously labor-intensive process is still frequently done by hand. And therein lies the bottleneck. The mounting labor shortage forced a jam manufacturer to find another solution. "We developed a strawberry machine for them. Instead of using a classic knife, we used a 'sharpened vacuum hose' that slices the fruit's crowns off. The hose sucks that crown away from the machine, so a clean product reaches the end of the line. The D-Blade does that with the same efficiency as a human, but much faster, so using the D-Blade, the manufacturer has a quick ROI."

S-Blade

"A Dutch French fries factory is currently using PIP Innovations' latest innovation - the S-Blade. With our other technologies, you can cut the black tips of fries very efficiently and at high capacity. The next three months will determine when the S-Blade will be on the market, but it should be by the end of 2023," Jeroen hopes. PIP-Innovations says the S-Blade will be marketed in different versions, thus making this functionality available to smaller producers.

"We keep getting asked, 'Can the D-Blade do that too," he concludes, adding that PIP Innovations is enthusiastically developing its uses for corn, parsnips, cauliflower, cucumber, and zucchini. Jeroen says the D-Blade offers many possibilities for different products and that, upon market demand, PIP Innovations is open to exploring new possibilities. When developing a new machine, the company is mainly concerned with further developing vision technology, robot control, and blades for the desired product. It does not build the machines; it outsources that to its partner VDL Systems, also in the Netherlands.

For more information:

Jeroen Pannekoek

PIP Innovations

Beukenlaan 61

5409 SX Odiliapeel

Tel.: +31 88 0227 201

jeroen@pip-innovations.com

www.pip-innovations.com