"We're currently seeing some issues regarding the sustainability of existing growing media. For starters, the disposal of the growing medium after usage, contamination of the product from the growing medium, supply chain issues due to the shortage of growing medium, legislative concerns, and the growing media is bulky and results in a high carbon footprint during transportation, which further complicated matters," says Beenish Siddique, Founder, and CEO of AEH Innovative Hydrogel Limited, a UK-based company.

Beenish Siddique.

In order to remedy these so-called issues, AEH has developed a gel-based substrate, also known as a B gross substrate. The substrate is a hydrogel that's derived from natural polymer, which is mostly for vertical farms, greenhouses, horticulturists, and even traditional farmers.

As the substrate consists of biological sources, it makes it more sustainable than other substrates on the market, as Beenish claims. The substrate is lightweight, easy to dispose of, disinfected, and highly biodegradable (95%), whereas the other 5% is compostable. The substrate comes in sheets, plugs, polymerized powder, and granules.

Cellulose materials are now used as the main base for gelponics. However, those are not all ingredients. Unfortunately, Beenish cannot give away too much about that as the patent will be available six to seven months from now.

AEH's gel-based sheets, plugs, and granules.

R&D base and trials

Launched in 2019, the Gelponics project is a collaboration between start-up AEH Innovative Hydrogel and CHAP Solutions. On top of that, the project is supported by the Graphene Engineering and Innovation Centre (GEIC) of Manchester University, Grobotic Systems, and CHAP partner Stockbridge Technology Centre (STC).

Trials with multiple crops of lettuce, basil, pea shoots, and microgreens are now tested together with CHAP and Stockbridge Technology Center. CHAP has helped the company to iterate its product to eventually launch a final product to market. AEH's newest manufacturing facility will be set up in Birmingham. Currently, the team is operating from their R&D lab in the Graphene Engineering Innovation Centre in Manchester.

The AEH sheets in trial.

AEH sheets

For growers that seek a light substrate for leafy green cultivation, the AEH sheets are a great fit as they provide a lightweight composition, offer stable pH levels, and have eco-friendly properties.

One sheet is 60 by 40 cm, which weighs 15 grams compared to traditional Rockstone matts, which are 200 grams. As the sheets come in a rather flexible format, they can be easily stored and moved around during transportation costs, which reduces the cost as well eventually. When being placed in water, the mats automatically absorb the water in order to expand and later for the seeds to be added onto the sheets.

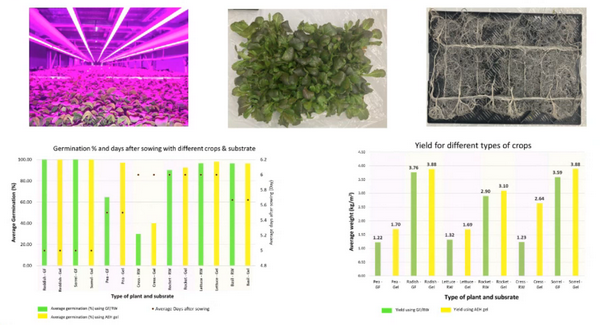

Results of AEH's growing media and traditional growing media. (Click here to zoom in on the photo).

Yield results

Comparable to the traditional growing medium, germination has reached slightly higher results than the growing medium. The yield of kg per crop, per m2, was, in general, similar to or higher than the traditional substrate.

As the samples are already sold to existing clients, AEH is now aiming to supply hydro sheets at scale by the end of this year. "At one of our clients, FLAX, for 3-4 days, there's no watering needed after seeding, as the gel holds a certain amount of water."

"When interacting with most of the growers, they prefer in-plug farming, especially for greenhouses, which is why we've added this product as well." For soft fruits, the plugs are currently tested in one of the largest strawberry-growing facilities in the UK. Since the trial is still going on, the results will be available next year.

The plugs are reusable, but throughout the cleaning process, you'd have to adjust the water temperature. When harvesting, the plant can be easily removed and the plugs reused. However, this is a limit of 3-4 times only.

As seen in the top, the product is seen dry at the top to prevent algae growth, and wet at the bottom to have plants grow effectively.

Multiple crops were tested with these plugs, like lettuces, basil, and leafy greens. Yet, these are also used for tomato propagation.

AEH Granules: improving open-field soil

The company's granules are used to increase the carbon and nitrogen content of the soil as it naturally has lower levels of those contents in it. It improves the soil moisture content and is derived from natural polymers.

Depending on what the customer is looking for, the team adds biostimulants to it as well, which is slowly released over time. However, the plugs also have a physical water retention base which helps to save on water. This eventually results in a yield increase of 20-30% and water saving of almost 20%, as Beenish claims.

As the plugs have multiple sectors they can be applied in, Beenish notes that there's a joint venture on the way that will allow them to focus on CEA and open field more specifically. However, Beenish and her team will be eyeing CEA more as they see more innovation ahead.

For more information:

For more information:

AEH Innovative Hydrogel

Dr. Beenish Siddique, Founder and CEO

Tel.: +44 (0) 786 750 2247

contact@aehinnovativehydrogel.com

https://aehinnovativehydrogel.com