South Africa faces significant challenges in managing its water resources due to being a water-scarce country, receiving 40% less rainfall than the annual global average. This has an impact on agricultural value chains, from the farm level to packhouse and cold storage facilities. In addition to water scarcity, the country is also facing an energy crisis, resulting in increased electricity costs, and the more stringent loadshedding measures that have been in place further intensify the energy-related pressures faced by fresh fruit suppliers. Moreover, global markets are increasingly demanding that fresh fruit suppliers showcase environmental sustainability in their production and processing operations, as part of the worldwide push to reduce carbon emissions.

To address these challenges, the Packhouse Action Group (PAG) Water Benchmarking Project was initiated in 2017 as an industry initiative to identify and manage water-related risks at the packhouse and cold storage levels of pome fruit value chains. In 2021, an electricity benchmarking component was added, and the project is now in its fifth year for water benchmarks and its second year for electricity benchmarks. Blue North Sustainability (www.bluenorth.co.za) manages the project and reports to the PAG Steering Committee.

The objectives of the project are to conduct a water and energy consumption benchmark study to highlight areas where packhouses can reduce usage. The project aims to replicate this objective annually, with an increase in packhouse participation and more detailed data collection around water and energy management and recycling practices. The project also aims to encourage industry knowledge sharing.

Throughout the project, water use data were collected for three packhouse areas: Packing Lines, Cold Storage, and Ablutions, Canteen & Offices. Electricity data were also collected for three packhouse areas: Packhouse operations, Controlled Atmosphere (CA) operations, and Regulated Atmosphere (RA) operations. Nine packhouses participated in the latest round of the project, and two more packhouses have expressed interest in participating in future data collection rounds.

Results from the 2021 calendar year of the project

The findings thus far have served as the foundation for ongoing improvement processes, as evidenced by the observed progress in water metering and data recording from the first year of packhouses participating in the project.

Only one packhouse could provide metered data for packing line water use, of which the benchmark was 607 litres/tonne pome fruit packed. The 2021 water use benchmarks for cold storage varied between 3 – 9 litres/Tonne.Day, while the benchmarks for the ablutions, canteen and offices ranged between 52 – 67 litres/person/day.

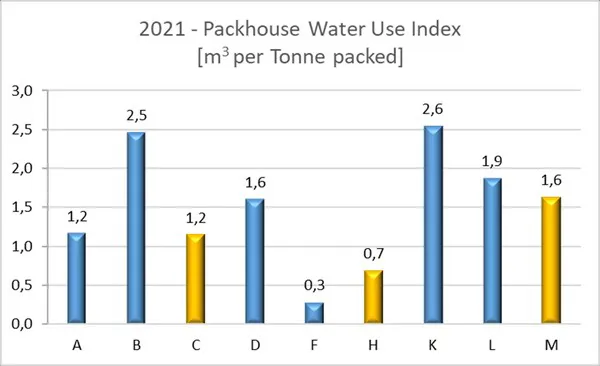

The overall water use index (Figure 1) for each packhouse incorporates water use for all sections of the packhouse, excluding water consumption allocated as “other”. Variation can be ascribed to different water management practices applied (e.g., flume drainage cycles, flume technology age, cold storage protocols, cold storage duration). The majority of packhouses consumed 1 – 2 m³ of water/tonne fruit packed.

For more information: hortgro.co.za