The company's know-how and knowledge of the products' organoleptic characteristics made it possible for PND to design a new generation of Williams pear processing machines.

Valerio De Caro

Valerio De Caro

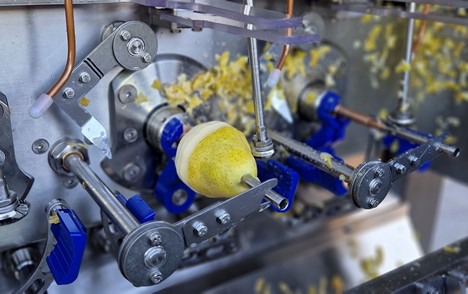

The PEARL6, a six-head pear peeler, de-seeder and separator, is unique and has many advantages and advanced technologies," says Valerio De Caro, the company's sales manager, "that differentiate it from the competition in terms of features, ease of use, maintenance costs and accessibility for washing and sanitizing all components.

The machine, built according to Directive 2006/42/EEC, has a production capacity of 72 fruits per minute and can be fed either manually, by operator, or automatically. The changeover is done by simply switching the mode with a key switch arranged on the control panel, without handling the automatic loader. The structure is made entirely of stainless steel and all mechanical parts insulated and protected by suitable guards to safeguard users. It is, then, equipped with a touch screen HMI monitor, through which it is possible to view the processing and adjust the phase systems, optimizing the product.

PEARL6 video

"Peeling," continues De Caro, "is suitable for any size of pear and different degrees of ripeness and firmness; there is, as a matter of fact, the possibility to process even very ripe fruit, without ruining the pulp. The quality of the fruit will not, therefore, be affected by its processing."

The optimization of the stem and grain system of the product results in increased yield, and the transmission system with toothed belts allows, on the other hand, the elimination of any noise. All tools, blades and wear parts, then, are easy to replace and adjust.

"Relying on PND means, therefore, receiving personalized assistance. The customer care turns out to be fast and effective and covers every latitude. The company, available for any ordinary and extraordinary maintenance, boasts highly specialized and trained multilingual employees, and an after-sales service that fulfills any request. Within an increasingly globalized and competitive market environment, being able to provide high quality products and constant care is an added value that makes the difference. What is its core strength? Listening to the customer who, at all times, is continuously assisted, from the design to the purchase and commissioning of the machinery," concluded De Caro.

For more information:

PND

info@pndsrl.it