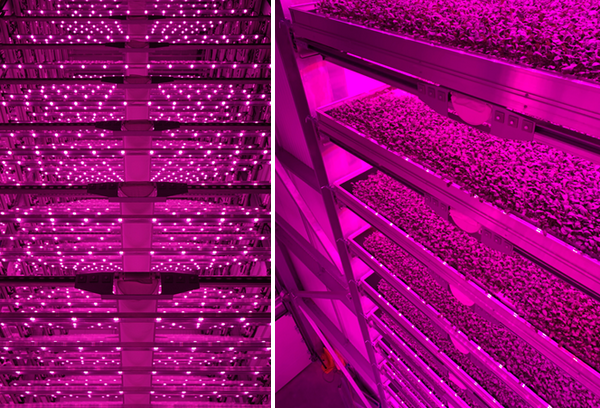

“It’s an exciting time here at Fischer Farms, there’s a lot going on. Our second farm, which has 25.000m2 of growing space is now ready. Investment in automation, and the installation of robots, help us consolidate labour costs. We’re very pleased with how the farm is looking.” says Tristan Fischer, Founder and CEO of Fischer Farms, a UK vertical farming company.

A corporate issue, and not specific to vertical farming

Since our latest chat in December 2021, Farm 2 is now ready and Fischer Farms has commissioned various pieces of equipment. Tristan shared that seeding would start no later than the end of February.

In a common trend, Tristan has seen the vertical farming industry suffer from setbacks, including bankruptcy and rising costs. Fischer Farms has had to deal with the same economic pressures all businesses are facing. However, the robust offering and financial backing that Fischer Farms has built, means they are facing the challenges with a positive outlook.

Tristan Fischer

“Vertical farming is in its infancy and we working to show that it is a truly viable alternative to field grown crops. We have taken giant leaps over the last few years, from technological advancements in equipment to renewable energy supplies. The potential of our new farm is even greater than we originally realised, especially in terms of scale. We’ve talked in the past about how important it is for vertical farms to be focused on being commercially attractive and matching field-grown crops, because of the very clear benefits around sustainability, traceability, and quality. But those benefits must be factored into the end cost, if we cannot compete on price with field-grown crops, people aren’t going to buy the produce.” Tristan explains.

Competing with same prices as open field

As Tristan elaborates, strawberry-picking robots can make the entire process so much easier. Instead of intensive labour costs seen in conventional strawberry farming, when the labour force must go to the plant, vertical farming allows for the strawberry plant to be brought directly to the robot. “This level of automation and cost-saving benefit is vertical farming’s ‘low hanging fruit’.”

“Scalability will allow us to price match conventional farming produce. Where other vertical farms might struggle with high product costs, it is our mission at Fischer Farms to make fresh produce accessible to more people. We want to feed the world with nutritional food.” It took Fischer Farms years to get here, and the investment in automation has helped them to balance the figures.

As Tristan emphasises, scale is important. He explains that it’s difficult to integrate vertical farming produce into the current retail supply chain as many retailers want a consistent offering for consumers. They would prefer 100% of a specific line of produce to come from vertical farming, rather than a mix of field-grown crops and vertically farmed crops. Yet, supermarkets are keen to take from vertical farms. A 365-day-a-year, consistently high-quality supply is a very attractive prospect. The link between a consumer’s needs and the reality of what a retailer can supply needs to be considered carefully.

More expansion to come

Leafy greens and herbs are just the start for Fischer Farms. To remain competitive on price, Tristan knows how crucial it is to forge on expanding, scaling and trailing products, demonstrating how robust a vertical farm offering can be. Short leafy greens are already in production, and fruiting crops, such as raspberries, blueberries and strawberries, are part of the farm 2 expansion.

Fischer’s aim is to scale production to rice, wheat and soy crops. That isn’t possible today, but Tristan is confident this is a very real prospect in the not-too-distant future. That’s why the company is focused on reducing costs through automation and, more importantly, powering the farms through 100% renewable energy. Fischer Farms has plans to take its model of farming globally.

Rising energy costs

Since its inception, Ficher Farms farm 1 has been connected to a large solar farm, meaning rising energy prices have been offset by the cheaper import of renewables. But that isn’t the case for farm 2. A solution, in the form of solar panels integrated into the design of buildings, means access to renewable energy is available, but there are other challenges surrounding this.

“A crisis can often result in imaginative solutions, attacking a problem from a different angle. This is what happened when we were faced with rising energy costs and limited access to renewable energy sources. The result is innovative, cross-collaboration between suppliers, stakeholders and talented Fischer Farm team members, to deliver an outcome that offers a reduced impact on cost, plus brings us closer to our phase two crop of soft fruits. This is one of many examples of why I believe vertical farming, and the enthusiasm within the industry, will prevail to provide sustainable solutions to food security.” Tristan adds.

For more information:

For more information:

Tristan Fischer, CEO

Fischer Farms

www.fischerfarms.co.uk