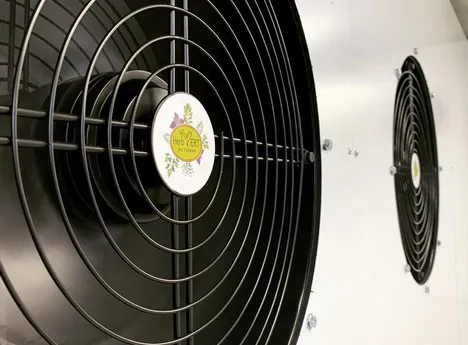

Originally developed for herbs and flowers - the Herb.ERT drying process is now used by numerous sustainably oriented fruit and vegetable growers to produce premium dried products and of highest quality. Recently, the drying oven has also been available as a modular container for soft drying of larger volumes. According to the manufacturer, what is particularly in favor of the solution in times of increasing electricity costs is that no additional heating is required for the heating process of the drying phase.

The Herb.ERT TC40 can be expanded on a modular basis, said Eduard Paschinger, who developed the process together with his business partner Bernhard Karstner. "This means that the output of the container can easily be expanded from 40 to up to 500 kilograms, which in turn corresponds to a drying area of 16 to 150 m2. This is particularly advantageous for rapidly growing processing capacities."

Numerous users from the agricultural sector (such as vegetable and fruit growers, herb producers, and mushroom cultivators) are already producing high-quality finishing products thanks to Herb.ERT.

Numerous users from the agricultural sector (such as vegetable and fruit growers, herb producers, and mushroom cultivators) are already producing high-quality finishing products thanks to Herb.ERT.

Furthermore, the "cluster module" design offers further advantages in terms of redundancy and reliability. Paschinger: "We do not limit the technology to one central technology unit; we but "cluster" several individual modules to one central module. This means that if an individual module fails, the remaining ones take over the drying task. If a central module were to fail, the system would be at a standstill until the defect is repaired. Furthermore, the plug-and-play replacement of system components results in reduced service and repair costs."

Heat-energy recovery and control intelligence

Unlike conventional drying processes (such as dehydrators), the Herb.ERT TC40 does not require additional heating. "The HerbERT-Dry-Soft process utilizes the so-called enthalpy of condensation - the latent heat that is present in every food product. This heat-energy extraction coupled with the interpolating control software is unique in the world."

Furthermore, the innovative process is equipped with intelligent automatic controls, Paschinger continues. In the central drying chamber, values are determined at four measuring points, and the zones are individually regulated by the automatic control system to the optimum drying ratio in each case. "High-quality metal alloys are used as condensation carriers, which ensure the most energy-saving heat transfer. With the technology innovations and the energy-saving drying process, our development team is convinced that we are setting sustainable standards in the future market of high-quality dry product production."

Images: Herb.ERT

For more information:

Eduard Paschinger & Bernhard Karstner

Herb.ERT

Dr.-Franz-Wilhelm-Str. 2

A-3500 Krems/Donau

Tel.: +43 (0) 650 4711100

office@herb-ert.at

www.herb-ert.at