TOMRA has launched in Chile the TOMRA 5X, a very efficient machine equipped with an X-ray sensor that allows the detection of a cherry's pit. It is a technological advance, developed by TOMRA Food that solves the problem of frozen fruit processors.

The IQF fruit market is going through a delicate moment. “The very high demand for IQF fruits in large consumer markets derived from the health panorama of recent years has generated an excess of stock abroad and the consequent slowdown in exports. Fortunately, it seems we'll pass the tipping point this year and exports will resume their growth as global consumption expectations continue to rise for this type of fruit,” stated Cesar Estrada, Area Sales Manager of TOMRA in Chile.

“Chile has a great reputation abroad thanks to the high quality of its fruit, food safety levels, and the seriousness of its entrepreneurs to conduct business. In fact, the last fresh cherry season was one of the best in recent years and continues to position Chile as a reliable producer, exporter, and strong global competitor. That's the reason we must always maintain the highest standards in this frozen product industry as well. In this sense, TOMRA helps its customers with specific solutions and state-of-the-art technology,” Cesar Estrada added.

TOMRA 5X: state-of-the-art technology to classify cherries and berries

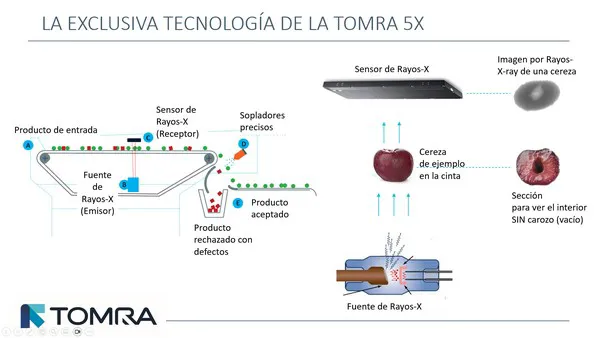

The TOMRA 5X is an X-ray sorter that inspects and sorts the flow of products based on their internal structure to ensure a quality product. It works by means of an X-ray generating source (emitter) and X-ray sensors (receiver). The product to be inspected passes between the emitter and receiver and the machine compares the different densities of the food itself and other higher-density materials that are considered contaminants.

“It is the only X-ray platform that inspects, detects, and sorts out the cherries with pits in pitless cherry production lines. The difficulty is that the density of the pits and the cherries are similar. However, TOMRA Food has solved this huge problem thanks to the latest advances in image processing algorithms,” Estrada stated.

This equipment can also detect foreign bodies, such as pieces of glass, stones, metals, high-density plastics, and rubbers, among others, so it is useful for other applications such as the classification of frozen berries to optimize the quality of the final product.

For more information:

TOMRA

www.tomra.com