At FPC Future, Scorpion Vision, a machine vision automation company, will present a brand new application for its AI-powered 3D vision platform. The new 3D+AI solution will enable fresh produce processors to automate the peeling, coring and chopping of apples without impacting yield for the first time ever. It has been conceived in response to calls from the sector for automation that can help combat unskilled labour shortages.

The new 3D+AI solution will enable fresh produce processors to automate the peeling, coring and chopping of apples without impacting yield.

Apple processing is an extremely labour-intensive task, but, until now, attempts at automation in this area have been unsuccessful. Both mechanical and 2D vision systems have struggled to contend with the inherent product variability, resulting in unreliable performance and unacceptably high waste.

As easy as apple pie…

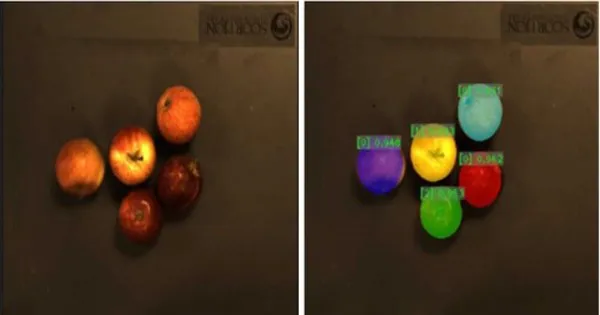

Scorpion Vision has overcome this challenge by deploying advanced 3D cameras with colour and shape measurement capabilities, and training them to identify and locate certain features (the pips, for example) using AI. This intelligence is then passed to a servo in the form of coordinates, and guides the robotic peeler, knife or corer to perform its action with millimetric precision.

The beauty of this approach is that the vision system can be taught to work with variability without it impacting on processing performance or accuracy. By applying AI to machine vision in its 3D Agritech camera, Scorpion has succeeded in achieving a very high level of repeatability, which is the key to high yield and minimal wastage. Yields of over 99% can be achieved with this bespoke combination of 3D vision and AI, compared with the yields of 70% that are typical for mechanical or 2D vision systems.

Scorpion Vision has deployed advanced 3D cameras with colour and shape measurement capabilities, and trained them to identify and locate certain features such as pips using AI.

Paul Wilson, Managing Director at Scorpion Vision Ltd, says: “We are excited to be bringing our proven AI-optimised vision technology to a new area of the fresh produce industry. It is the first time that a commercially viable solution for automating apple processing has been available. In this respect, AI has been a game-changer - providing the missing link that was needed to build vision-guided robotics that can guarantee high yields in spite of variable subject matter.”

Scorpion’s 3D+AI solution has been tried and tested in a range of produce applications, from topping and tailing corn on the cobs, swedes and leeks, to de-coring lettuce, removing the outer leaves from sprouts and de-shelling seafood.

For more information:

Paul Wilson

Scorpion Vision

Tel: +44 (0) 1590 679333

www.shop.scorpion.vision