Patatas Meléndez recently opened a brand new, fully automated plant in Valladolid, Spain. Deprez Construct, from Belgium, and Wyma, an international company, supplied most of the fully automated washing and sorting line. "It's a first for us, too, to have combined all automatic aspects in this capacity. It's a wonderful project with an impressive result," begins Deprez Construct's Mattias Mergaert.

Treating potatoes like apples

The tale began with this Spanish potato company's owner, Javier Meléndez. "He really wanted to build a 'factory of the future'. He came to us because he was familiar with our other installations at places like UDAPA, a cooperative near Patatas Meléndez. Javier was eager to have his potatoes treated like apples. He, thus, requested only the best, and after hearing our (Deprez and Wyma) story, everyone was convinced to start working together."

Falling as little as possible

The rest, as they say, is history. Wyma handled the potato receiving, cleaning, washing, and optical sorting, and Deprez took care of handling, internal transport, and the entire system's full automatic control.

"It was important that the product drop as little as possible, as low as possible throughout the entire installation. The unavoidable drops were also to be into water to cushion the potatoes' fall. That's what happens in apple processing. And everything's planned so capacity can be doubled again soon; that's possible," says Mattias.

"A conveyor belt transports the potatoes, in crates, from one zone to another. Before entering the washing line, they're sorted into three sizes. Then you can put the larger and smaller potatoes aside to be washed later. Those unwashed products are collected and go to an automatic crate warehouse, where they can be stored for the longer term. The remaining potatoes are then (pre)washed and then optically sorted."

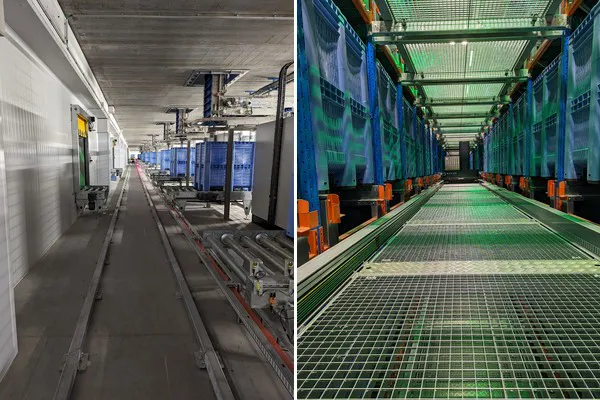

Automated crate warehouse

Once optically graded, everything is collected in 800kg plastic crates, and the washed potatoes are stored alongside the unwashed product in the crate warehouse. "There, the crates are stored and automatically sent to the right destination. For unwashed potatoes, that's the washing line. For the washed ones, the packing line, on the other side of the warehouse," Mattias continues.

"Our Meteors transport everything there. These shuttles take full crates to the right locations and return empty crates to the filling areas. The Orbiter, our automatic crate tipper, empties the crates into the appropriate packing line. A Meteor then removes the empty crates, and the process begins anew. This is a well-known Deprez system. It was great to build a system, with all the trimmings, of this size, from start to finish. The potatoes are fully traceable too, from when they're received to being placed on the pallet," Mergaert explains.

Fully automated

The potatoes are barely handled in this plant. "Patatas Meléndez has also automated shipping. Every truck is automatically prepared for immediate loading. No one operationally handles the potatoes anymore. There are only operators and possibly maintenance personnel."

"The only time someone touches the potatoes is when customers opt for manual sorting. They also often want to inspect the product at the last minute. We can, thus, still meet that demand, but it's not used often. Just about everything in the plant is fully automated," Mattias concludes.

For more information:![]() Deprez Construct

Deprez Construct

129 a Lichtervelde Street

8610, Kortemark, Belgium

Tel: +32 (0) 515 81 491

Email: info@deprez.be

Website: www.deprez.be