"There is large demand for our fruit sorting and packaging machines, regardless of the fruit segment," Palm Systems Sales Manager Matthias Kinzel tells us. The company offers sorting, packaging machines and automation solutions for processing different types of fruit such as apples, pears, cherries, etc. for companies of all sizes.

"In most cases, the sorting machines that we integrate from our partner companies Elisam and Perfect form part of the overall process that Palm Systems offers its customers. We focus on efficient and fruit-friendly handling such as wet emptying, drying, crate refilling and packaging of the fruit specialized."

Worldwide clientele

"The ubiquitous shortage of skilled workers, regardless of the industry, is increasing the demand for automated solutions," says Kinzel. Furthermore, due to the international network of the company, a correspondingly higher demand can be covered. "The machines are in great demand primarily in Europe and North America, but also in South Africa and Australia."

"The requirements of our customers are constantly growing and are becoming more and more detailed. Depending on how the apples are processed, for example, the apples have to be sorted into different categories according to size, colour, outer and inner quality and weight. All these parameters can be controlled via the software of the sorting machines adapted and sorted according to the most diverse customer requirements."

Course of the sorting and packaging plant

The performance of the machines and the associated machine equipment are based on individual customer requirements. "In front of the sorting machine, large crates of apples, pears or cherries are emptied into the water tank in a gentle way. For more effectiveness, the crates are tilted in the water tank for emptying, creating an efficient crate change and an almost continuous occupancy of the downstream machine," Kinzel explains.

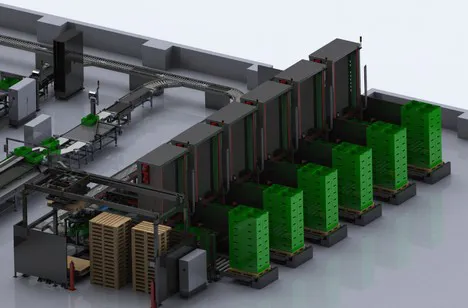

"After emptying, the fruits are, if desired, taken out of the water in order to sort out damaged or muddy goods. If desired, the fruits can also be cleaned with a specially developed brushing machine, which can also remove rust, for example, before they are then sent to the sorting machine. There, they are sorted according to the customer's requirements -size, colour, weight and quality- and then they are assigned to the associated outlets. At the outlets, the fruits are stored in water channels in order to be fed, for example, via a collection channel to the large box refilling in the water bath. The filled large boxes are then placed in their picking area, which they are assigned by the software using a Palm Portal stacking robot.

Up to 30 tons of goods sorted

"Depending on the manufacturer, the sorting machines are available with 2 to 8 lanes running in parallel and can be equipped with 6 to 85 outlets, depending on the desired number of qualities and capacity. Different equipment means that smaller companies, for example, can use a four-lane sorting machine with up to 6 tons /h possible. Depending on the feed systems, up to 30 tons/h can be achieved with sorting machines with six to eight lanes."

Kinzel also tells us about a project that was recently implemented at a customer who put a new sorting station into operation. There, the apples are washed via a portal wet emptying system. Then they are fed into the sorting system. "35 sorting channels are coupled to the system, designed in a particularly short design, in which the goods are collected, stored and filled back into crates via the refilling and commissioned via the portal stacking system. This entire process is controlled by Palm's in-house software."

6-fold palletizer front

Delayed supply chains

At the start of 2023, the delayed supply chains will still cause some delays here and there. However, Palm Systems was able to build up a good stock of individual parts and components, for example in the electronics sector. "The delivery times of the manufacturers have definitely increased in the last two years. Instead of two weeks back then, we are now often being faced with six to eight weeks. With more extensive controls, the waiting times can be more than 1/2 year. But one also has to be flexible, always looking for alternatives."

Images: Palm Maschinen GmbH & Co. KG

For more information:

Matthias Kinzel

Palm Maschinen GmbH & Co. KG

Ostfeld 23, 21635 Jork

Tel.: +49 4162 90 79 9-0

E-Mail: mkinzel@palm-systems.de

Internet: www.palm-systems.de