An innovative de-nitrification bioreactor project at a pineapple farm on Queensland's Sunshine Coast is achieving some impressive environmental results for not only the industry but also the health of the region's waterways - with hopes that more farmers can look into installing the simple technology.

The pineapple bioreactor implementation trial was completed this year at the Sandy Creek Pineapple Company farm. It was funded by the state's Department of Environment and Science (DES) and is part of the South East Queensland Water Quality (SEQ) project, managed through Growcom. One of the project's leads from DES, Stephanie Cooper explains it is important that industry has recognised the need for change to improve environmental outcomes and ensure sustainability.

"It's quite complex, but we need to think about the small changes that we can make to have that overall better outcome," Ms Cooper said. "Collaboration is key, and you have to find the right people to talk to and partners to get the right outcomes. I know it has been a tough time for the pineapple industry, so something like this may be the last thing some want to think about, but I also know industry members care about where they live in the wonderful areas of Queensland and want to keep it this way. We all know that there can be impacts on what happens on the farm in the broader environment. DES does invest in a range of on-ground actions, research, training, monitoring, and reporting to improve environmental outcomes for water. We have been working hard to remove the big three; sediment, nutrients and pesticides from entering waterways."

"It's quite complex, but we need to think about the small changes that we can make to have that overall better outcome," Ms Cooper said. "Collaboration is key, and you have to find the right people to talk to and partners to get the right outcomes. I know it has been a tough time for the pineapple industry, so something like this may be the last thing some want to think about, but I also know industry members care about where they live in the wonderful areas of Queensland and want to keep it this way. We all know that there can be impacts on what happens on the farm in the broader environment. DES does invest in a range of on-ground actions, research, training, monitoring, and reporting to improve environmental outcomes for water. We have been working hard to remove the big three; sediment, nutrients and pesticides from entering waterways."

The 2021 South East Queensland report card showed there were increasing pollutant loads in the Pumicestone Passage, which flows into internationally renowned wetlands Moreton Bay. The department has not only been highly monitoring the creaks that lead into the Passage but also launched a program for seed funding, as a next phase of the project, to help financially support growers to implement initiatives like bioreactors on their farms.

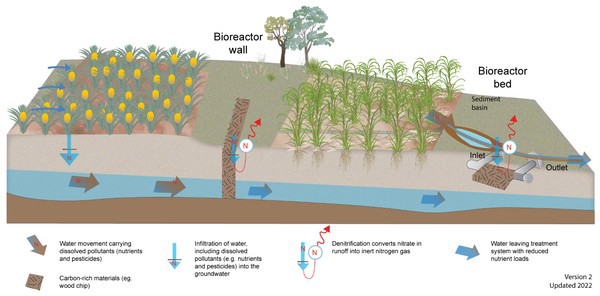

Farm manager at Sandy Creek Pineapple Company, and Chairman of Australian Pineapples, Sam Pike says wall bioreactors were installed at the perimeter of the farm, which is strategically placed where there is a lot of subsurface water movement and high nitrate concentrations - meaning the water will now run through the bioreactors before reaching the local waterways. He says the actual physical labour involved in installing the bioreactor took just a couple of days, and it is basically a trench with woodchip in it.

Farm manager at Sandy Creek Pineapple Company, and Chairman of Australian Pineapples, Sam Pike says wall bioreactors were installed at the perimeter of the farm, which is strategically placed where there is a lot of subsurface water movement and high nitrate concentrations - meaning the water will now run through the bioreactors before reaching the local waterways. He says the actual physical labour involved in installing the bioreactor took just a couple of days, and it is basically a trench with woodchip in it.

"The water quality issue is not going to go anywhere, it's going to be here for good," Mr Pike said. "We can bury our head in the sand and not do anything about it, and that will probably be the end of the industry because we need to be proactive with what we are doing on farm and understand that we are impacting the environment. The (science and research) reports are coming out saying that it (polluted runoff) is unhealthy for the environment and if it keeps happening, there will be regulations enforced. If it gets to regulation, we'll be done. After experiencing the past six months installing the bioreactor and working with DES and SEQ, I have found it to be a really good process for the whole industry - we now have some good relationships. It shocked me a bit - I didn't think it would be as easy as it was. The technology already existed, and we were very happy to do it on a proper scale and make a difference. This is our industry and I don't want to see it go anywhere. I encourage everyone to put their hands up and start talking to people and listening, I have found the government departments more than willing to help."

Photo: Sandy Creek Pineapple Company's Sam Pike; below, Dr Stuart Irvine-Brown from QDAF.

The scientific goal of the bioreactor is to achieve de-nitrification

Queensland Department of Agriculture and Fisheries (QDAF) Dr Stuart Irvine-Brown explained that Mr Pike's farm is relying on a natural nitrogen cycling process to transform nitrate in groundwater into nitrogen gas - it is a natural process involving little greenhouse gases. The bioreactor creates a home for naturally occurring bacteria, and the woodchips provide a food source and convert the nitrate in the water into normal nitrogen gas.

"There are really simple pieces of technology, like this bioreactor, that we can implement in the right place at the right time to reduce the rate of nitrogen transfer from agriculture production areas into the surrounding aquatic environment," Dr Irvine-Brown said. "The woodchip does the same process that a normal wetland would do. To make it work, you need to put it where the nitrate is, so we have made a perimeter around the (Sandy Creek) farm. The idea is to find out where the nitrate is, and put woodchip there to intercept and interact with the groundwater - it is that simple. The longer it is in there, the better removal rate you get; from our work a few years ago, we found the residence time, or longer the water sits in with the woodchips is important in how much nitrate is taken out."

"There are really simple pieces of technology, like this bioreactor, that we can implement in the right place at the right time to reduce the rate of nitrogen transfer from agriculture production areas into the surrounding aquatic environment," Dr Irvine-Brown said. "The woodchip does the same process that a normal wetland would do. To make it work, you need to put it where the nitrate is, so we have made a perimeter around the (Sandy Creek) farm. The idea is to find out where the nitrate is, and put woodchip there to intercept and interact with the groundwater - it is that simple. The longer it is in there, the better removal rate you get; from our work a few years ago, we found the residence time, or longer the water sits in with the woodchips is important in how much nitrate is taken out."

Pineapples need nitrogen to grow, but after events such as heavy rainfall, it can lead to a flushing of the soil and excessive nitrate in waterways leads to algal bloom, which can be toxic to the broader environment and affect the balance of the whole ecosystem. Dr Irvine-Brown added that in the case of the Sandy Creek bioreactor, a width of around 30 centimetres is enough as the water passively moves through, the bacteria take the nitrate and convert it to nitrogen gas.

There are examples of bioreactors working effectively in New Zealand for the past 25 years, but while this technology is not solving the problem of keeping nitrogen in the soil under the pineapples where they are needed, it has importantly stopped the nitrate from exiting the farm.

For more information

Growcom

Phone: +61 7 3620 3844

growcom@growcom.com.au

www.growcom.com.au