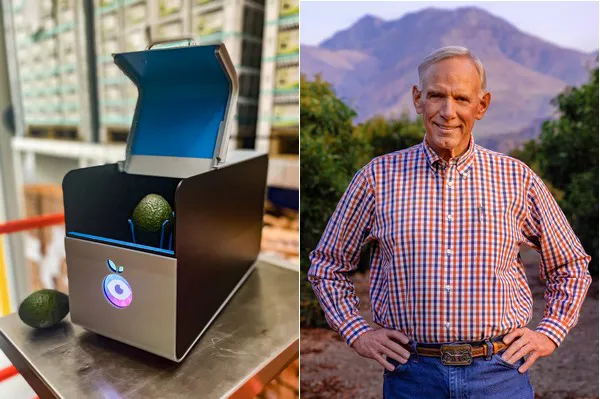

Mission Produce announced the advancement of its ripening process in the United Kingdom (UK) with AVOS Mini, a non-destructive ripeness control tool and smart device that measures avocado ripeness and provides quality management insights. The device is being used for the first time in the company’s state-of-the-art forward distribution center (FDC) located in Dartford, UK and is expected to reduce food waste and promote product quality and reliability.

“We are committed to innovation and dedicated to providing high-quality fruit to our customers,” said Steve Barnard, chief executive officer. “With AVOS Mini, we are quickly advancing our ripening capabilities in the UK on the heels of our FDC launch in April. By promoting a positive consumer experience with ripened avocados, we strive to drive avocado demand, support our customers’ avocado category development and grow our presence in the UK market.”

“With AVOS Mini, we are quickly advancing our ripening capabilities in the UK on the heels of our FDC launch in April," says Steve Barnard.

“With AVOS Mini, we are quickly advancing our ripening capabilities in the UK on the heels of our FDC launch in April," says Steve Barnard.

AVOS Mini is a non-destructive quality control tool that measures fruit firmness and quality without puncturing or bruising the fruit, replacing the standard penetrometer. Built by Experience Fruit Quality (EFQ), a company creating solutions for non-destructive quality control, AVOS Mini is expected to reduce fruit destroyed per container during ripening checks by approximately 67 percent, according to sample procedure trials performed by Mission and EFQ.¹

“We invest in sustainable solutions to reduce our environmental impact,” added Barnard. “This provides an opportunity to reduce food waste at the operational level as part of our commitment to preserving our resources and protecting the health of our planet.”

The device is being used for the first time in the company’s state-of-the-art forward distribution center (FDC) in Dartford, UK.

The device is being used for the first time in the company’s state-of-the-art forward distribution center (FDC) in Dartford, UK.

AVOS Mini also uses artificial intelligence to provide advanced ripening data and analyses according to fruit size and season, which is expected to streamline the ripening quality control process and contribute to enhanced operational efficiencies.

“Data provided by AVOS Mini enables the company to make optimal process adjustments, supporting the company in ripening avocados to customer specification, whilst significantly reducing the number of avocados needed for destructive testing,” said Marco de Jong, chief executive officer, EFQ.

The use of AVOS Mini and its accompanying services are contracted to Mission in exclusivity through the end of 2023 in the UK market. AVOS Mini joins Mission Produce UK’s portfolio of advanced ripening technologies, including its Mission Control atmosphere control process, which helps create optimal environments for ripening.

For more information:

For more information:

Jenna Aguilera

Mission Produce, Inc.

press@missionproduce.com

MPUKSales@MissionProduce.com

¹AVOS Mini trials conducted by Mission Produce and Experience Fruit Quality. 2022