Reefer floor covers enable fruit exporters to maintain the quality of their products, reduce food waste and have fewer financial losses due to claims during transportation

Reefer containers are the fastest-growing segment within the container shipping market. Reefers are used for temperature-sensitive products, mainly food, flowers, plants, and pharmaceuticals. Over the entire course of the supply chain, starting from the production and finishing with the consumer, the temperature should be maintained as close as possible to the benchmark temperature. Prolonged deviation of this temperature can lead to the deterioration of the product quality, ultimately leading to total cargo loss (Castelein, Geerlings, & van Duin, 2020).

Hence, keeping temperatures stable and within the product’s requirements is a must during transportation, as this is one of the lengthiest parts of the supply chain (Coyle, Novack, & Gibson, 2015). Thereupon OTFLOW, a Dutch company that improves shipping conditions, developed an innovative floor cover that creates the optimal air circulation in reefers and, therefore, provides stable and homogenous temperatures all over the container.

When not using OTFLOW and having incorrect export conditions, there will be not only implications for the products’ quality but also significant economic and environmental consequences. The food industry is particularly known for its sustainability issues since there is a large number of lost goods. According to the United Nations, 50% of all fruits and vegetables that are produced on the planet are wasted each year. Approximately two-fifths of all food produced for human consumption is lost or wasted. The Food and Agriculture Organizations (FAO) reported that 40% of food waste occurs in the supply chain (van Est, 2021).

All the above factors result in significant financial losses for the industry. That is why OTFLOW decided to launch this month, their Benefit Calculator. With this tool, companies can estimate the financial savings they can achieve when implementing better shipping conditions.

What is OTFLOW?

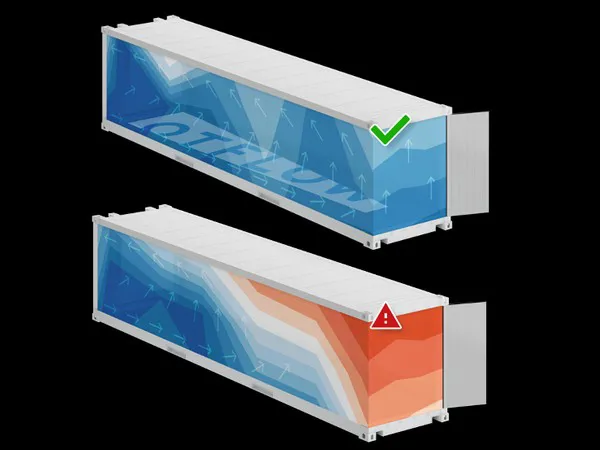

OTFLOW is a company that specializes in airflow optimization for cargo containers. Together with the University of Wageningen, they developed a floor cover with the most effective shape to provide optimal airflow during reefer transport. With this innovative solution, OTFLOW helps to reduce food waste, maintain product quality, and minimize financial losses due to claims. Without OTFLOW, the internal airflow in a container is inadequate; this results in ‘hot & cold spots’ that lower the cargo’s quality and cause significant financial losses.

However, it has been proven by the Wageningen Biobased Research Facility that by implementing this floor cover, the cold air reaches all corners of the containers, thus maintaining an ideal temperature from front to back. This solution can be used for all the different commodities transported in reefers.

For more information: farmersreviewafrica.com