Last week, an article was published on trials of growing strawberries under retractable flat-roof cooling houses in Irapuato, Mexico. At the same site, at 1,700 m. elevation, raspberries were trialed. The high elevation causes sun radiation to be high year-round, and trials started with transplanting tips on April 8 to create the optimum control strategies for the roof and misting system through the hot and dry summer conditions. A second transplanting of tips was done on June 10, targeting a harvest date during the high-priced winter season. The results of the first transplanting are shared in this article.

The demonstration center was built by Cravo Equipment, with support from Giddings, Black Venture, and BerryWorld. The objectives of the raspberry trials were to:

- Determine optimum control strategies for the retractable cooling roof and misting system during the summer and winter.

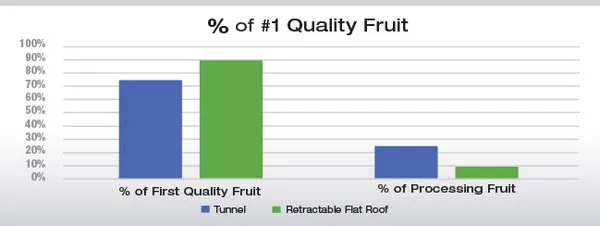

- Increase total yield as well as increase the % of #1 quality fruit.

- Reduce the use of agrichemicals and the total number of spray applications per month.

The cooling roof retracted when the leaf temperature exceeded 16°C, and the roof closed for 95 percent as soon as the leaf temperature exceeded 26°C. The misting system was activated to maintain a minimum of 40 percent relative humidity.

Impact on yields and quality

The trials were done with the Diamond Jubilee raspberry variety, and the results are compared to the yield and fruit quality of the same variety grown under conventional tunnels at local commercial growers. “For the tips that were transplanted on April 8, we were able to increase the plant density in the retractable roof by 22 percent, from 13,000 to 15,873 plants per hectare,” says Cravo’s Richard Vollebregt. In addition, number 1 fruit quality per plant for the primocanes increased by 32 percent under the retractable roof from 621 to 821 grams per plant, and the total yield for the primocane harvest increased by 61 percent from 8,073 to 13,032 kg per hectare.

Total #1 quality in the retractable flat roof would have been higher, but the extensive rains in the summer during the flowering period caused bees to be inactive and pollen to be wet, which resulted in a reduction in pollination. Pollination during the winter season, on the other hand, was 100 percent as there was minimal rain.

Impact on spray applications

With the improved control over light, temperature, and humidity under the retractable cooling roof, an average 91 percent reduction in foliar disease and a 76 percent average reduction of insect pressure was experienced. “This dramatic reduction allowed us to alter our spray program,” said Vollebregt. “We reduced our use of agrichemicals by 75 percent and increased the number of organic spray applications by 50 percent.” This led to a 50 percent reduction in the total number of spray applications per month.

The trials are continuing with the floricane production for the crop planted in June, and a new trial of long cane raspberry plants were transplanted on December 6, 2022.

For more information:

For more information:

Richard Vollebregt

Cravo Equipment Ltd

Tel.: +(1) 519 759 8226 x 215

richardv@cravo.com

www.cravo.com