An international greenhouse solutions company hopes to expand its presence in Australia and New Zealand with the latest automation projects for fruit and vegetable production in greenhouses.

Certhon Group Business Development Director Edwin Vanlaerhoven says that one of the company's main focuses is to use technology to make high-tech growing successful.

"Robotics will become an important part of controlled environment agriculture (CEA)," he said. "The integration of systems is becoming more important, and for the plant factories, the market needs to be developed. This will bring new opportunities for potential customers to distinguish themselves from the current market. Also, robotics can also help in the area of food safety."

Based in the Netherlands, Certhon has worked on several major greenhouses and indoor farms around the world, including strawberry production in the urban environment of Hong Kong, and is also developing a high-tech 5,000 square meter indoor to grow tomatoes in the Abu Dhabi desert. In 2020, one of the largest automotive technology suppliers in the world, DENSO, announced its investment in Certhon to expand the horticulture business in the global market and collaborate to develop and provide greenhouse solutions.

"We are going to combine the strengths of our green fingers with their knowledge of using technology, robotics, data systems, AI, and manufacturing principles," Mr. Vanlaerhoven told the recent Protected Cropping Australia Conference. "It will be in two different ways; we want to give better tools to growers to make the climates and give them a wider span of control, and also the automation in the greenhouse itself, as there is a shortage of workers and people to pick the fruit and do crop treatments. Combining our strengths will literally give new inputs to high-tech horticulture and make it more available to newcomers to the industry.

"Before our new co-owners, we never really had a strong focus on Australia because we never really had a presence here, so we did more of our business in the Northern Hemisphere. However, we did build a project in Tasmania, and with our DENSO colleagues who have a strong presence here, we can foresee plenty of business in the Australian market."

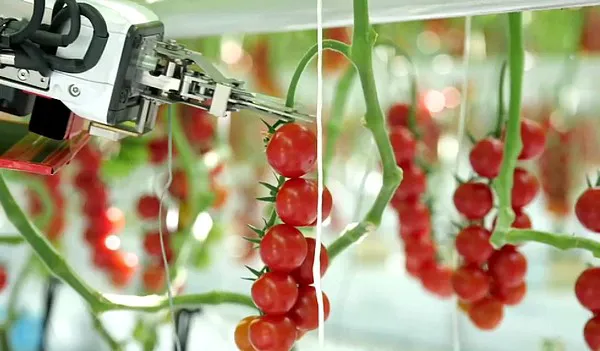

One of the robotics that the company has launched to the market is a harvesting robot for tomatoes, which is currently in operation in Japan. The company is already working on bringing its new prototype to market next year.

"The robot is fully autonomous and harvests cherry vine tomatoes," Mr. Vanlaerhoven said. "We chose cherry vine tomatoes because the labor of harvesting is a big percentage of the cost of growing these types of tomatoes. Among other places in the world like Netherlands and Canada, we hope to introduce to Australia as all these places have a shortage of workers. Later it will be further developed to harvest cocktail vine tomatoes, and then medium and large vine, and then also into cucumbers and bell peppers. It is fully autonomous and theoretically can work 24/7, but harvesting at night can be difficult. We prefer around 16-18 hours a day. It can harvest up to 20 kilograms an hour, stack up to four boxes of tomatoes, and work with multiple robots in a greenhouse. Hygiene is important, so it can disinfect itself."

Apart from greenhouses, the other track the company is working on is plant factories. Around ten years ago, Certhon built a robot for leafy green (salad) cultivation in a Dutch vertical farm, which is being used for the germination and propagation of young lettuce plants that are being transplanted automatically. Since then, the company has built more of these facilities, although not all have a vertical farm situation. Mr. Vanlaerhoven explains that growers can have a homogeneous crop as no one physically touches the crop, and using this automation gives the plants a perfect start. Theoretically, a facility can be built in Australia for an almost autonomous greenhouse.

Another "revolutionary" project that is still a work in progress involves strawberry and tomato crops, where automation means that people do not have to go inside the facility, and the fruit can move around to a central place for harvesting. It may mean that fruit like strawberries can stay on the plant longer to ripen and improve the taste.

But Mr. Vanlaerhoven says the most exciting innovation that the company is working on is autonomous production of tomatoes in plant factories, which currently can produce 60 kilograms per square metre of cherry plum tomatoes.

"We are are the owner of some genetics, together with a breeding company, and we have looked toward a totally different type," he said. "We always say that tomatoes in the greenhouse are 20 or 50 metres long, as it is all for human interaction. Historically, the plants are smaller and don't grow vertically, but in this case, we designed a system of movable tomato plants. They ripen all at once, and we have proven that to ourselves several times by going through several cycles. They are on a mobile gutter system, so we give them the perfect start in a controlled environment and in an indoor farm they will be set to fruit all at once, then the second part can be done in a greenhouse that uses less electricity. After we do five growing cycles of this in a year, the plants go to a harvester and the plant will be demolished and the tomatoes will be taken out. This will be the future of tomato cultivation in indoor farming, as we can guarantee the output."

The first customer to grow with this system will be in America this year and is expected to follow in other countries soon after.