How do you know if a peach is sweet without taking a bite? That is the challenge for researchers working on new hand-held sensing technology to measure the sweetness of any peach you point it at, and any nectarine, plum or apricot too, for that matter.

The device is one of three technologies being developed and tested in a new project launched today (Wednesday) by Food Agility Cooperative Research Centre (CRC).

Sensors for Summerfruit is a 2.5-year $1.1 million Food Agility CRC project led by Agriculture Victoria in collaboration with RMIT University, Summerfruit Australia Ltd, and Australian technology companies Green Atlas and Rubens Technologies.

Food Agility CRC Chief Scientist Professor David Lamb says the ultimate goal of the project is to help growers get the right piece of fruit to the right consumer at the right time.

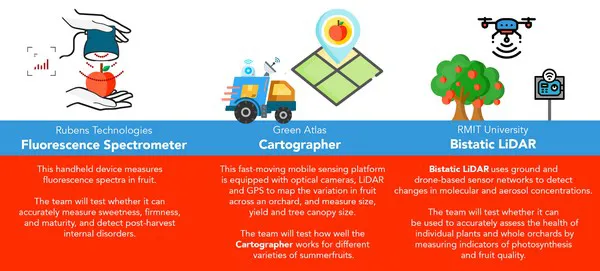

“From orchard to export, data-driven decisions are key. Two of the sensors, RMIT’s Bistatic LiDAR and Green Atlas’ Cartographer, will operate in the orchard helping to assess health status and predict fruit size, yield and maturity,” says Professor Lamb.

“A third sensor, Rubens™ Fluorescent Spectrometer, will be put to work in the packing sheds to detect sweetness, firmness and robustness for transport. It’s the closest thing to tasting the fruit, without actually taking a bite.”

The sensors will be calibrated on Agriculture Victoria’s Tatura SmartFarm in Goulburn Valley, and then road-tested in commercial orchards and packhouses in Goulburn Valley, Swan Hill, Cobram, and Sunraysia.

Research Leader Crop Physiology at Agriculture Victoria Dr Ian Goodwin says the project aims to benefit the Summerfruit sector by growing export markets and improving their operations.

“Fruit is downgraded or redirected at the harvesting and packing stages because it doesn’t meet consumer preferences for that market or, if fruit is harvested too early or too late, the quality can deteriorate in transit,” says Dr Goodwin.

“Using these sensors, we could help growers tailor their practices to grow the fruit consumers want, triaging fruit in the packing sheds, and only exporting those robust enough to make the journey.”

Summerfruit Australia Ltd CEO Trevor Ranford said the project would focus on the Chinese market but would ultimately be relevant to any export market for Australian stone fruit.

“We have spent years improving our understanding of consumer preferences,” said Mr Ranford.

“For example, when it comes to nectarines, our Chinese consumers prefer yellow nectarines that are sweet and low in acid, with a redder skin colour.”

This depth of consumer understanding has seen Australian Summerfruit exports increase annually by an average 12 per cent for the last 10 years.

“In the 2019/20 season alone the industry exported over 21,000 tonnes of stone fruit worth $89.11 million,” said Mr Ranford.

“This project takes it to the next level, helping us refine those requirements and make decisions along the supply chain to grow high-quality fruit that looks, tastes and feels perfect to Chinese consumers and consumers in more than 40 other export markets.”

For more information:

For more information:

Trevor M Ranford

Summerfruit Australia Ltd.

Tel: +61 417 809 172