Major Chinese sorting solution company Reemoon says it is aiming to be fully licenced in Australia by the end of July, allowing it to have service technicians close by to its existing projects across the country - following its latest successful install of the Fruscan S7 Pro in New South Wales.

"Our aim is to build a one-hour service window for reaction," Vice Director Dennis Clock said. "Our name will be Reemoon Sorting Australia Pty Ltd, and it is currently under the registration process. That means in Griffith we need at least one engineer. If we get more projects nearby in Leeton, then we will get another one. We will have another Waikerie and another in Mildura, and the fourth one will be in Mundubbera in Queensland. Only in this way can we provide a one-hour reaction to our after-hours service. Service is important to Reemoon, at the beginning after installation, we will send one service technician or engineer to stay in the customer's packing shed. After a month of training and getting the compatibility right, then we will leave. We have a good advantage because of our service, so we need to keep doing this."

To view the Photo Report of the Clear Lake Citrus visit click here.

While the company is based in China, Mr Clock explained that Reemoon manufactures turn-key sorting machines for post-harvest operations. The company started when a Navel orange grower in China, used to send the fruit to other packing sheds before his son made the decision to build their own packing shed and needed to buy a sorting machine. From there came the idea to create a sorting machine that was not as expensive as others on the market to sell to other growers.

"We are 22 years old and quite young in comparison to some brands in other parts of the world like Europe, USA or New Zealand," Mr Clock said. "As a farming family, the founders knew very well that it was not easy for farmers to get the money to afford sorting technology. We handle the process from the bin tipper, right through until the end of a complete sorting line mainly for fruits and some vegetables, like tomatoes. Our technology history from around 20 years ago, which was an electronic sorter in China and around the year 2000 it was very popular as it was advanced technology to be used in packing sheds. In 2019, we built a 30-lane complete sorting line (turnkey project) with 18 internal quality detectors for Brix, which was a big project in China. We use near-infrared (NIR) and IR besides colour cameras for the quality detector and we have multi-camera and multi-angle video systems in the past 3-5 years."

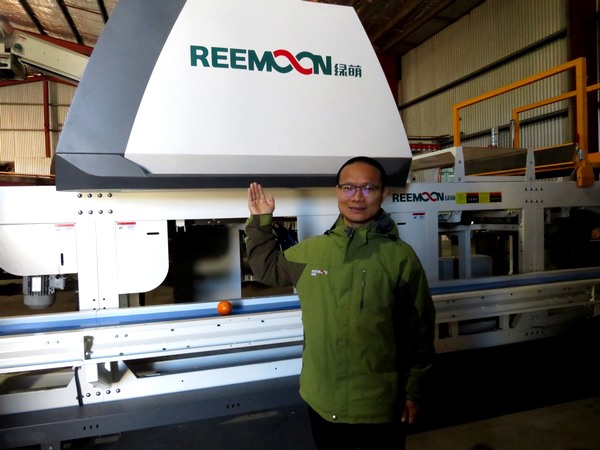

Photo: Dennis Clock

The company now has five customers in Australia, more than 2000 customers in China and 420 customers worldwide, and the machine is not only used on citrus but a wide range of fruit from apples to pineapples, small melons and even kiwifruit and avocados.

Reemoon's most recent Australian installation was at Clear Lake Citrus is based in Griffith in the New South Wales Riverina, which it started using the new machine and software this season. More than 22 fresh produce companies from Australia's south attended a presentation and site visit to see Reemoon's Fruscan S7 Pro four-lane grader in action last week, with people coming from as far away as South Australia and Mildura to attend the citrus company's packing shed.

The Fruscan S7 Pro is a multi-angle six-camera system (3 IR and 3 Colour) for one lane and it takes images from 3 angles one 90 per cent straight above and the other two from 45 per cent angles.

"It gives the grower a big advantage as it can sort more varieties of blemishes, and can recognise the blemishes clearer, and deeper," Mr Clock said. "It can detect the light or tiny blemishes very clearly. In this season, due to too much rain, growers are having more blemishes or problems such as rot, split and albedo."

Clear Lake Citrus is a family-run business that was established around 26 years ago. It has just started with its own fruit, specializing in Navel and Valencia oranges, but packs for 50 other growers who supply them with their fruit, and it supplies not just domestically but is now getting back into the exports.

"The reason I went with Reemoon was that we have been to their factory and saw how they make the graders," Managing Director Patrick Mancini said. "Reemoon has used high-quality materials. Again, a big thing with Reemoon is that when they put a new machine in, they ensure that you have a technician that stays with you until you are comfortable letting the machine run on your own. The support we have received is second to none." It improves productivity because we can say more definitively that it is a grade one, or grade two, or a premium piece of fruit. We are not having to sort the fruit by using more labour, and it does the job more accurately. We are confident in giving customers exactly what they want."

Photo: Shane Jensen

Shane Jensen, from Jensen Industries, was one of the electrical engineers to work on not only Clear Lake's sorting machine but other projects from Reemoon. He says the value that the customer gets means that it is good value for big growers right down to the smaller farms.

"It's a full installation from start to finish and the customer gets what they want," he said. "It's just value for money; what you get for your money is incredible. They come out and install the machinery and everything gets commissioned at the end and when you walk down and see the bins the fruit comes out in the correct grade. The quality of the equipment is very quality gear and very affordable for even a small packing company. The equipment came in multiple shipping containers and was very well packaged. Luckily a technician from Reemoon came over and was allowed in straight after COVID-19 (border restrictions eased). It went together really well. The new software is included with the machine, I think it will be a bit of an eye-opener to a lot of people when they see what the product is at the end of the machine. People will be amazed at what the technology from Reemoon can do."

For more information

Patrick Mancini

Clear Lake Citrus

Phone: +61 2 6962 7659

office@clearlakecitrus.com.au

Dennis Clock

Reemoon

Whatsapp:+86-182 7070 6759

overseas1@reemoon.com.cn